I. Superior Product Protection and Formula Stability

The core advantage of the Square Airless Lotion Pump Bottle lies in its unparalleled ability to protect the integrity of the contents. The airless pump mechanism utilizes a mechanical piston instead of a traditional dip tube, fundamentally altering how the product is dispensed and stored.

1. Eliminating External Contamination Risks

Traditional pump bottles risk allowing air to flow back into the container after dispensing, which can lead to oxidation, degradation, or microbial proliferation of the contents. The airless system uses a rising piston to push the product out, maintaining a vacuum or near-vacuum state inside the bottle. The square airless bottle maintains this benefit while ensuring total isolation from external air, bacteria, and contaminants through its integrated sealing architecture. This makes it the ideal choice for active ingredients such as high-concentration Vitamin C, Retinoids, or natural extracts that are highly sensitive to light, heat, and oxygen.

2. Precise and Consistent Dosage Control

The design of the airless pump engine allows for extremely accurate metered dispensing. Standard pump outputs can be precisely calibrated to , , or , and the repeat accuracy during continuous pressing is exceptionally high. This precision ensures that consumers receive a consistent, effective amount of product with every use, significantly boosting confidence in the product's efficacy.

3. Achieving Ultra-Low Residual Rates

Conventional packaging often leaves a product residue ranging from to due to limitations imposed by the dip tube length and bottle bottom shape. The piston design of the airless bottle travels tightly against the inner wall, expelling almost the entirety of the contents. By optimizing the geometric fit tolerance between the bottle base and the piston in the square design, product residue can be reduced to less than . This not only saves cost for the consumer but also demonstrates the brand's commitment to maximizing resource utilization.

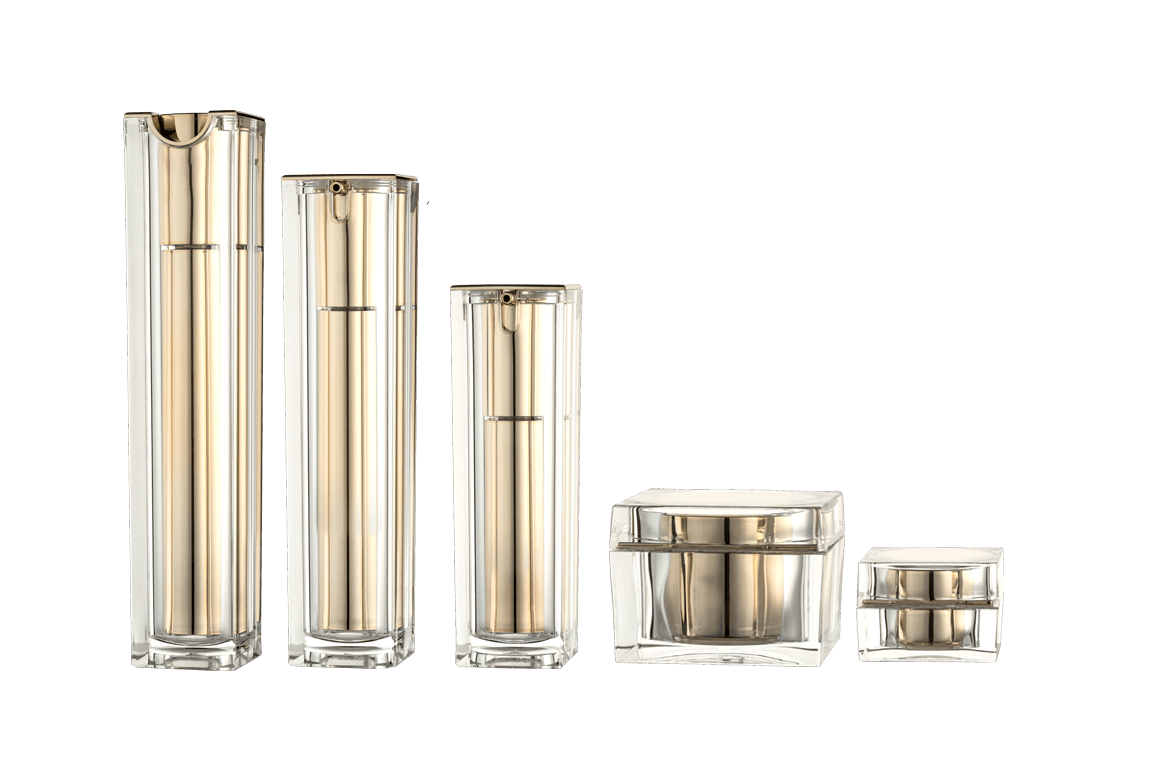

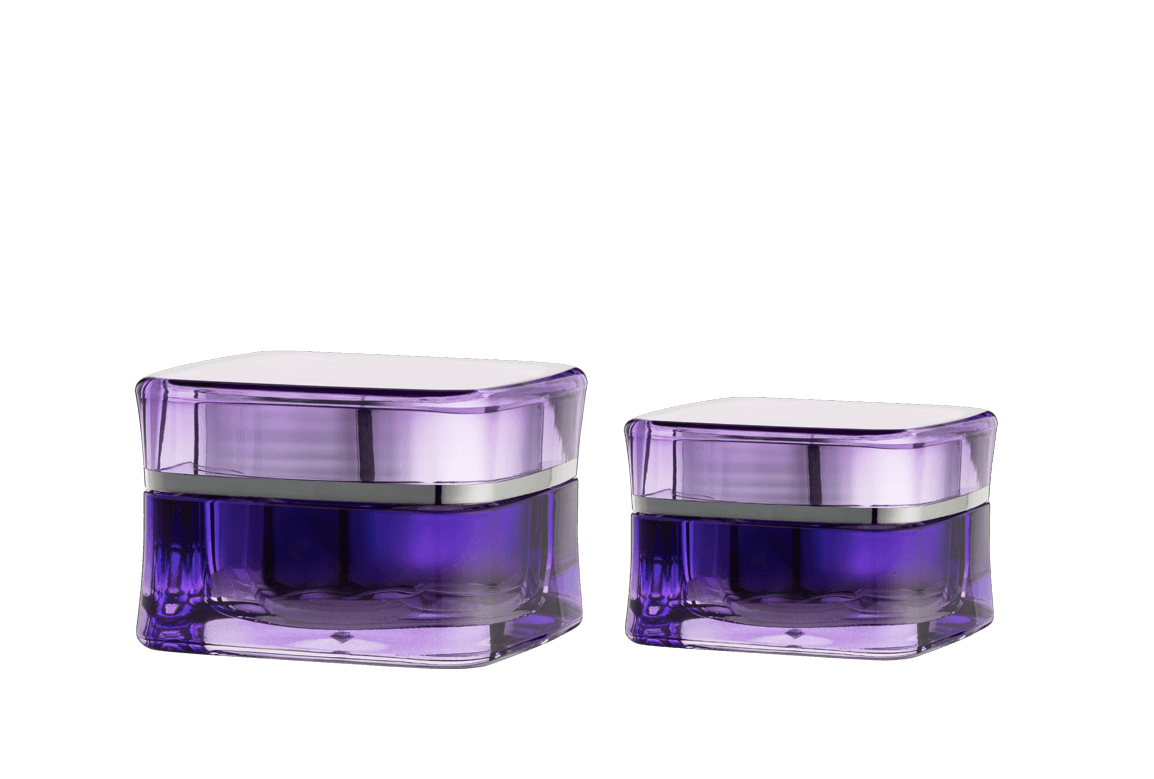

II. Structural Aesthetics and Brand Differentiation

The square format is more than a visual variation; it is a strategic choice for packaging structural engineering and brand positioning.

1. Geometric Stability and Shelf Impact

The square bottle body offers excellent lateral support and stacking stability. On the retail shelf, the crisp, angular silhouette and clean edges instantly distinguish the product from its round counterparts, achieving significant visual focus. This design language is often strongly associated with modernity, professionalism, high quality, and precision engineering, helping the product rapidly establish a premium market identity.

2. Maximizing Print and Decoration Surface Area

Compared to curved bottle surfaces, the square bottle provides four expansive, flat printing and decoration surfaces. This greatly facilitates high-resolution screen printing, intricate hot stamping, heat transfer printing, or the application of large, clear labels. Designers can leverage the full planar area for complex graphic designs, detailed product information display, or unique textural finishes, enhancing both the information communication efficiency and the artistic value of the packaging.

3. Ergonomic Optimization for User Experience

From an ergonomic perspective, the square shape often provides a more secure and easier-to-grip feel than round bottles. This is particularly advantageous for larger capacity packaging, as the square cross-section effectively prevents slipping when hands are wet. Furthermore, many high-end square airless pumps integrate a twist-to-lock or snap-lock mechanism into the design, further enhancing the product's portability and resistance to accidental dispensing, thus improving the user's daily experience.

III. Manufacturing Process and Supply Chain Value

The production of Square Airless Pump Bottles demands more meticulous mold design and stricter quality control, inherently signifying advanced manufacturing capability.

1. Rigorous Mold Design Challenges

The square bottle design must overcome multiple technical difficulties inherent in injection molding. While round bottles have naturally uniform wall thickness, the corner transition zones and side walls of a square bottle are prone to uneven cooling rates, leading to internal stress, sink marks, or dimensional deviations. Advanced manufacturers must rely on high-precision multi-cavity molds and hot runner technology to ensure the wall thickness uniformity and geometric tolerances of the square bottle are maintained at the micron level, critical for smooth, friction-free piston travel within the chamber.

2. Compatibility with Automated Filling Lines

Although the square geometry adds complexity to the gripping and indexing on filling lines, modern high-speed filling and assembly systems are precisely adapted. Specialized suppliers can provide customized pucks and guiding systems necessary for square bottles, ensuring high-precision alignment, filling, and pump capping operations are completed without compromising production efficiency. This capability to handle complex shapes is a key standard for assessing a supplier's expertise.

3. Driving Sustainable Material Innovation

The prevailing trend for high-end square airless bottles involves the adoption of recyclable mono-materials (such as an all-PP structure). To meet the requirements for rigidity and aesthetic appeal while maintaining recyclability, manufacturers invest heavily in material formulation, co-extrusion technology, and the simplification of internal components. The square design helps showcase the brand's technical commitment and environmental promise in packaging sustainability, aligning with the growing global consumer demand for green consumption.

Chinese

Chinese España

España Italia

Italia Le français

Le français