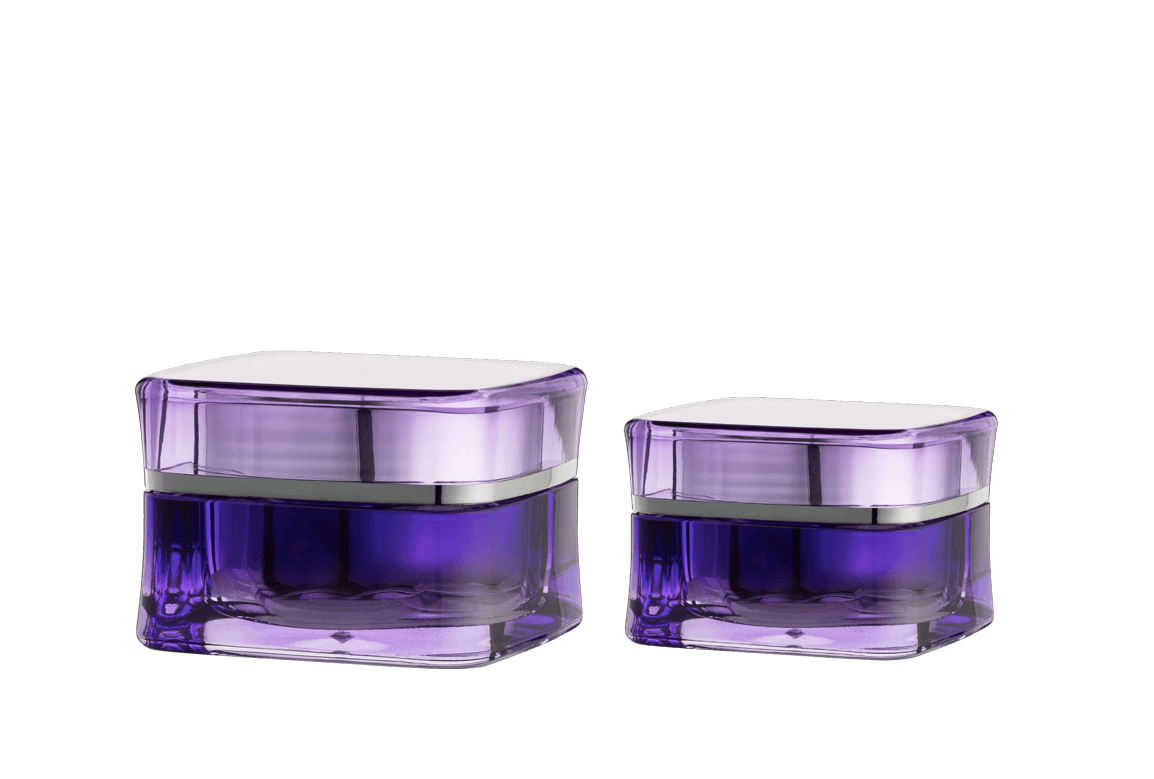

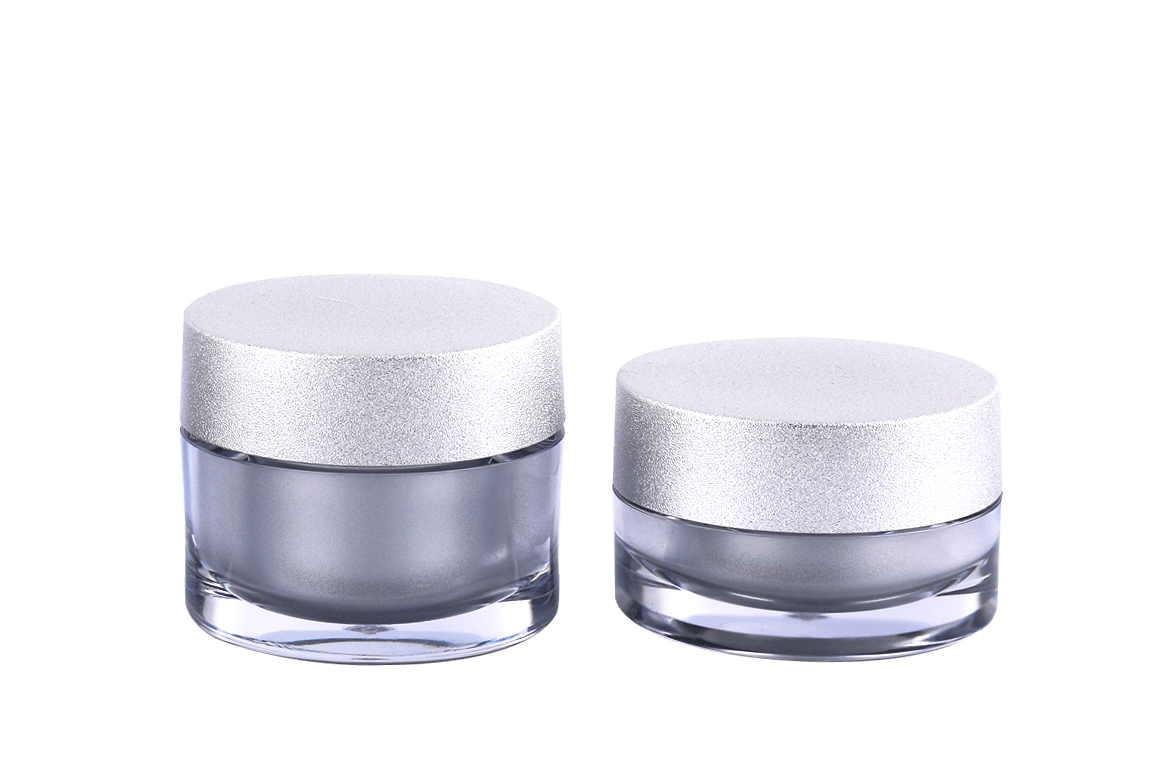

Cream bottle is one of the main containers for cosmetics. It has a large caliber, thicker wall, and the material is composed of acrylic and glass. In this article, we mainly analyze the basic quality requirements of cream packaging materials:

Basic appearance requirements of cream bottle

1. Foreign matter: Do not mix with dust, flying insects, hair and other debris

2. Appearance: no cracks, flashes, burrs, stains, oil stains, scratches, scratches, ghosts, etc.

3. Short plastic/unsaturated mold: the product is incomplete and seriously affects the overall appearance

4. The container is broken: the contents cannot be filled, and the function and overall appearance have been affected

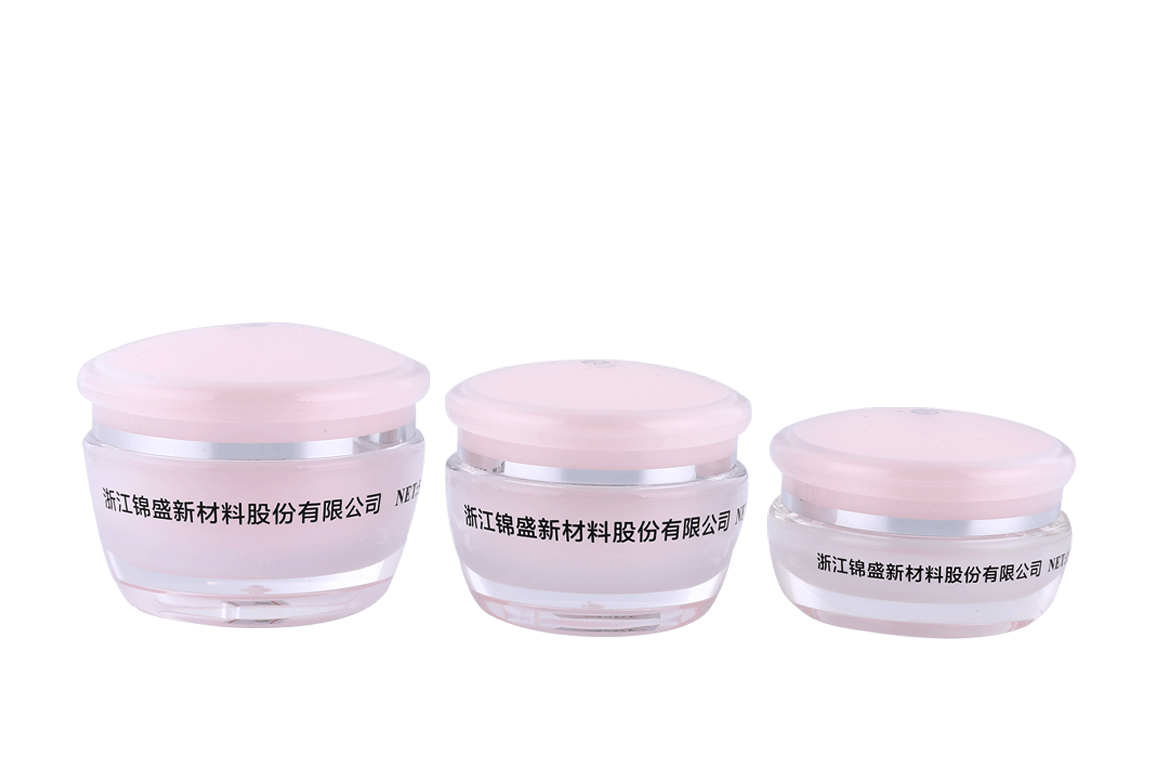

Requirements for surface treatment and graphic printing of cream bottles

1. Painting: electroplating, spraying, dot or linear bottoming, pitting, etc., should be within the limit

2. Ironing / layout: must be consistent with the design seal, printed text or pattern ghosting, uneven or jagged edges, missing dots, color dots, etc., shall not affect the overall product appearance and the ironing pattern and should be in Within the limit (color dots shall not appear on the logo and within 0.5cm near it)

3. Surface chromatic aberration: must meet the signing standards

4. Characters: characters or patterns must be indispensable, the fonts are incomplete, the printed fonts appear broken or incomplete, and it is not easy to distinguish the original fonts

5. Ink pollution: 1mm2↑ ink adhered to the product surface (different color points are equivalent)

6. Hot stamping/printing adhesion: Use 3M-810 tape to stick it for 1 minute and then pull it off quickly at an angle of 45° to 90°. There should be no obvious peeling off to expose the bottom, and the font should be clearly visible.

7. Electroplating/spraying adhesion: Use a utility knife to draw 4-6 squares about 0.2cm in length on the electroplating/spraying part (scratch the electroplated/sprayed coating is enough), use 3M-810 tape After sticking to the square for 1 minute, pull it off quickly and firmly at an angle of 45°~90°, without falling off.

Material and structure requirements of cream bottle

1. Specifications/size: meet the standard and within the limit

2. Material: Do not use inappropriate raw materials and materials for production and assembly

3. Gate: must not appear, it will shake when standing

4. Thread: no slippage, affecting function and overall appearance

5. Deformation: the bottle and cap cannot be matched

6. Gap: The matching gap is not allowed to exceed the standard by more than 0.5mm

7. Positioning: the positioning is beyond the standard ±2mm or more

Functional requirements for cream bottles

2. Pull-out force between the outer cover and the inner cover: Use a pull-out force tester to test the pull-out force between the outer cover and the inner cover should be ≧4 kgf (39.23 N).

3. Vacuum leakage test: Fill the product with water and lay it (or upside down) on the absorbent white paper in the vacuum box. Vacuum for 15 minutes, the loss rate shall not exceed 0.5%.

4. Vacuum box air pressure: The product material is ordinary material -0.06MPa, and the product material contains volatile components: -0.08MPa.

5. Drop test: It is filled with water and dropped at a height of 1m, there is crack, looseness or abnormal function

Chinese

Chinese España

España Italia

Italia Le français

Le français