In the high-end cosmetics packaging market, acrylic (PMMA) holds a prominent position for its exceptional transparency and crystal-clear appearance. Double-walled design is a key technology that enhances the value and protective properties of acrylic containers.

1. Protective Barrier: Maintaining Formula Stability

The primary purpose of the double-walled design is to provide superior product protection and maintain formula stability.

Thermal Insulation: The double-walled design creates an air barrier between the outer acrylic (PMMA) layer and the inner container. This air gap acts as an effective thermal insulator, significantly mitigating the impact of external temperature fluctuations on the product within. This thermal buffering capability is crucial for cosmetics containing natural active ingredients, emulsifiers, or heat-sensitive serums and creams, helping to prevent emulsion breakage, deterioration, or decreased activity due to temperature fluctuations, thereby extending shelf life.

Impact Resistance: The additional outer acrylic shell significantly enhances the container's structural integrity and durability. During transportation, storage, and daily use, the double-layer structure more effectively absorbs shock and pressure, reducing the risk of cracking or leaking the inner container due to impact. This is crucial for ensuring consumers receive their products intact.

II. Visual Luxury: Enhancing Brand Image and Perceived Value

A double-layer structure is a direct means of enhancing the perceived value and brand image of cosmetics.

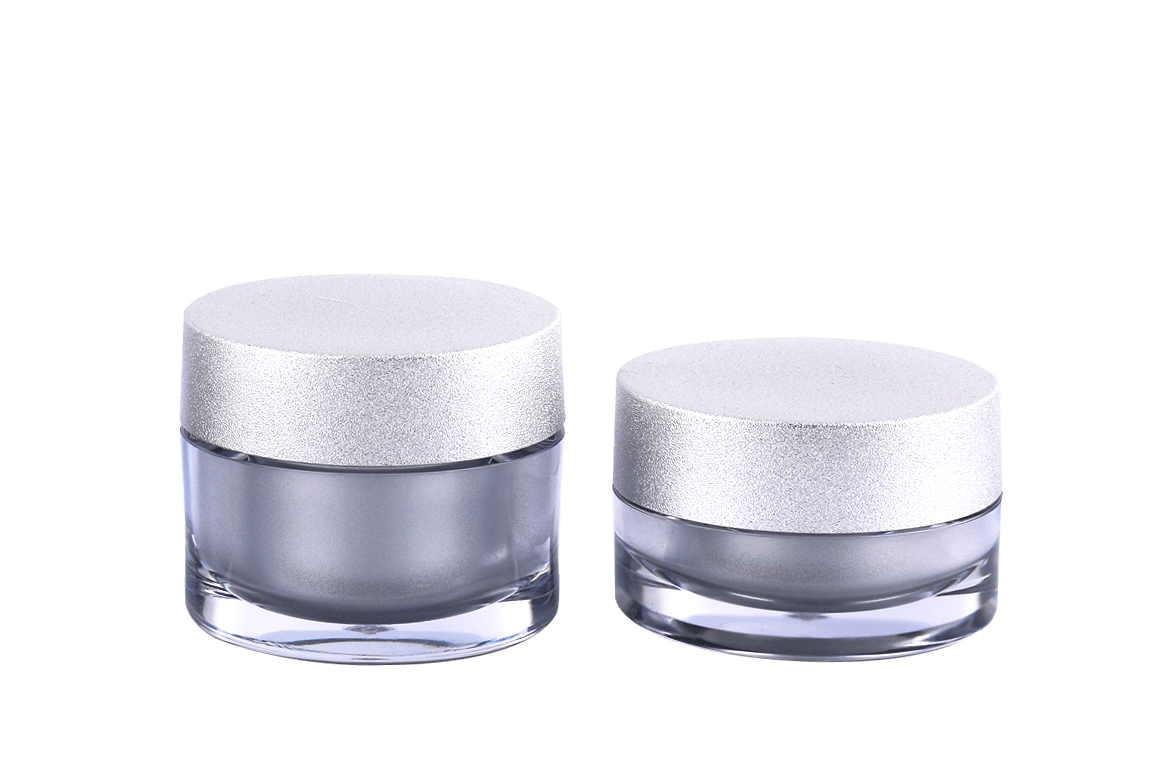

Visual Depth and Three-Dimensional Sense: The high gloss and transparency of acrylic are maximized through the double-layer design. Light reflects between the outer and inner layers, creating a unique sense of depth, brilliance, and weight. This three-dimensional effect is unmatched by single-layer plastic containers and directly suggests the product's high-end and luxurious positioning.

Tactile and Weight Perception: Compared to thin, single-layer containers, the double-layer design significantly increases the overall weight and feel of the container. When consumers pick up the container, they perceive a solid, weighty feel, which psychologically associates it with high quality, price, and meticulous craftsmanship, further solidifying the premium brand image.

Design Aesthetics and Customization: The double-layer structure offers a wealth of customization possibilities. The outer layer can be transparent, frosted, or gradient acrylic, while the inner layer can be opaque or metallic PP/AS. This color contrast, surface treatment, and material combination between the inner and outer layers provide brands with tremendous design freedom, facilitating the creation of a unique visual identity.

III. Functional Implementation: Compatible Pump Heads and Vacuum Systems

Technically, the double-layer structure also provides the necessary structural support for certain specialized functions.

Compatibility and Liner Isolation: Not all cosmetic formulas are suitable for direct contact with acrylic. For example, some formulations containing solvents or alcohol may cause stress cracking in acrylic. Double-layer containers utilize a more chemically stable inner liner (such as PP, AS, or PETG) for direct contact with the product, while retaining the aesthetically pleasing acrylic outer shell, seamlessly addressing formula compatibility.

Support for Airless Pump Systems: Some airless bottles utilize a double or triple-layer construction, with the outer layer providing sturdy mechanical support. This structure is crucial for ensuring a tight seal and smooth piston advancement, ensuring the product is kept out of contact with air during use, effectively preventing oxidation and secondary contamination.

Chinese

Chinese España

España Italia

Italia Le français

Le français