PETG Transparency

PETG (modified polyethylene terephthalate) is an amorphous copolyester material with a high transparency approaching that of glass. Its light transmittance is typically around 90%, and its refractive index is moderate, resulting in a clear and bright visual effect. The introduction of ethylene glycol into PETG's molecular structure reduces its tendency to crystallize, maintaining excellent optical uniformity. When PETG is used in cosmetic bottles and jars, the surface is smooth, free of visible crystals and impurities, allowing the color and texture of the contents to be clearly displayed.

Transparency Differences from Glass

Glass has long been considered the epitome of transparent packaging materials, with a visible light transmittance exceeding 92% and a higher refractive index, creating an extremely clear and crystalline appearance. In comparison, PETG's transparency is slightly lower than that of glass, but the difference is not significant in practical applications. PETG's advantages include being lightweight, shatter-resistant, and safer during transportation and use. For the cosmetics packaging industry, PETG offers a near-glass-like transparency while avoiding the safety hazards and increased costs associated with glass breakage.

Comparison of Optical Properties with Acrylic

Acrylic (PMMA, polymethyl methacrylate), known as "organic glass," is extremely transparent, with a light transmittance of 92%-93%, approaching optical-grade glass. PETG has a slightly lower light transmittance than acrylic, but its impact resistance far exceeds that of acrylic. While cosmetic jars made of acrylic are aesthetically pleasing, they are susceptible to cracking or shattering when dropped or subjected to external impact. While PETG lacks the extreme transparency of acrylic, it meets the clarity and presentation requirements of cosmetic packaging, while offering a better balance between safety and durability.

Differences in Gloss and Refractive Index

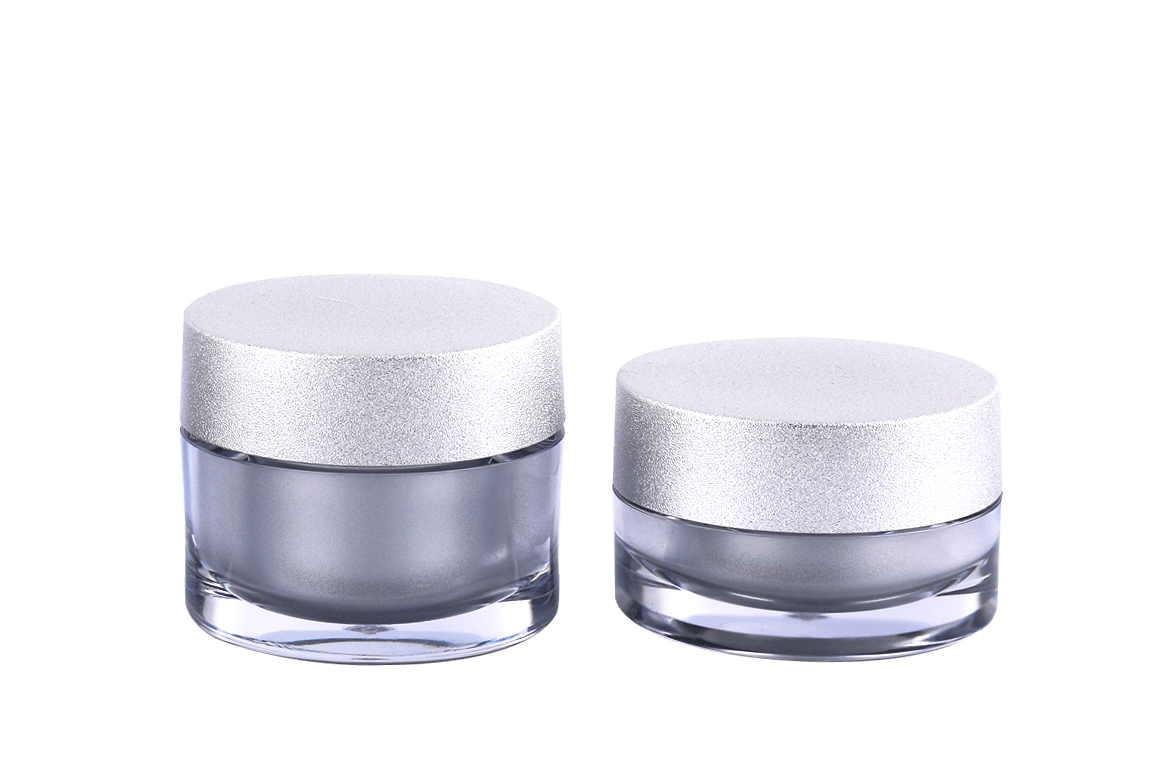

Glass and acrylic have high refractive indices, resulting in strong refraction and reflection of light, giving the surface a high gloss and a crystal-like texture. PETG has a slightly lower refractive index, resulting in a more natural and soft visual effect. In cosmetics packaging, these optical properties give PETG cans a simple, elegant, transparent appearance, adapting to different product positioning. For high-end products, external coating or spraying can enhance the gloss. For product lines emphasizing naturalness and environmental friendliness, PETG's softer optical effect better aligns with the brand's tone.

Transparency Stability and Lifespan

Glass rarely experiences a loss of transparency over long-term use unless scratched or damaged. Acrylic easily yellows under UV exposure, significantly reducing its transparency. PETG surpasses acrylic in terms of optical stability. The material itself has excellent UV resistance and a low tendency to yellow. Under common storage and transportation conditions for cosmetics packaging, PETG maintains its transparency and optical uniformity over time, reducing visual aging issues.

The Impact of Processing on Optical Performance

PETG offers excellent thermoforming and injection molding properties, making it easy to produce highly transparent products. Compared to acrylic, PETG is less susceptible to stress cracking during the molding process and has a lower rate of surface defects. Glass products require high-temperature melting and molding, resulting in high processing costs and limited design flexibility. PETG offers advantages in mold design and production efficiency, making it easy to create complex shapes like thick-walled cans and curved bottles while maintaining excellent transparency. For the cosmetics industry, PETG meets the optical requirements of display while accommodating both mass production and personalized design.

Chinese

Chinese España

España Italia

Italia Le français

Le français