In the high-end beauty industry, cosmetic bottle sets are more than just containers for products; they serve as a crucial barrier to protect them from contamination, maintaining their potency, and effectiveness throughout their lifecycle. Their expert design and meticulous craftsmanship create a scientifically rigorous fortress for their contents, ensuring that every drop of serum and every swipe of cream remains as pure and potent as the day it was first produced.

1. Material Selection: The First Line of Defense Against External Intrusion

Ensuring product contamination throughout its shelf life begins with the choice of bottle material. Different cosmetic ingredients require varying levels of chemical resistance from packaging materials.

Glass Bottles: Glass bottles are the preferred choice for highly active liquid products like perfumes and serums. Glass is chemically inert and does not react with the contents, ensuring ingredient stability. Furthermore, dark glass bottles (such as brown or green) effectively block UV rays, protecting photosensitive ingredients (such as vitamin C and retinol) from degradation by light.

Plastic Bottles: PET (polyethylene terephthalate) and PP (polypropylene) are common plastic materials. PET is transparent, lightweight, and shatter-resistant, making it suitable for products like creams and lotions. PP, with its excellent chemical and high-temperature resistance, is widely used in products requiring high corrosion resistance. When selecting plastic bottles, rigorous material compatibility testing is essential to ensure that the bottle will not release harmful substances that could affect product quality.

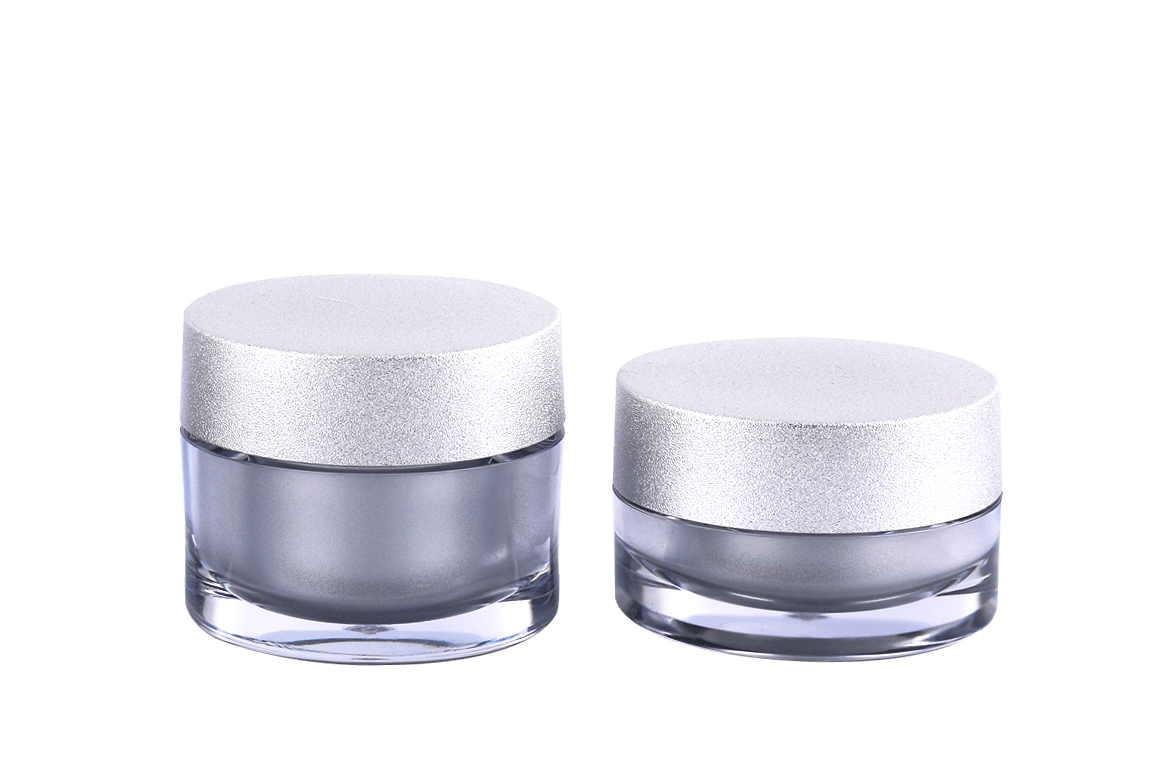

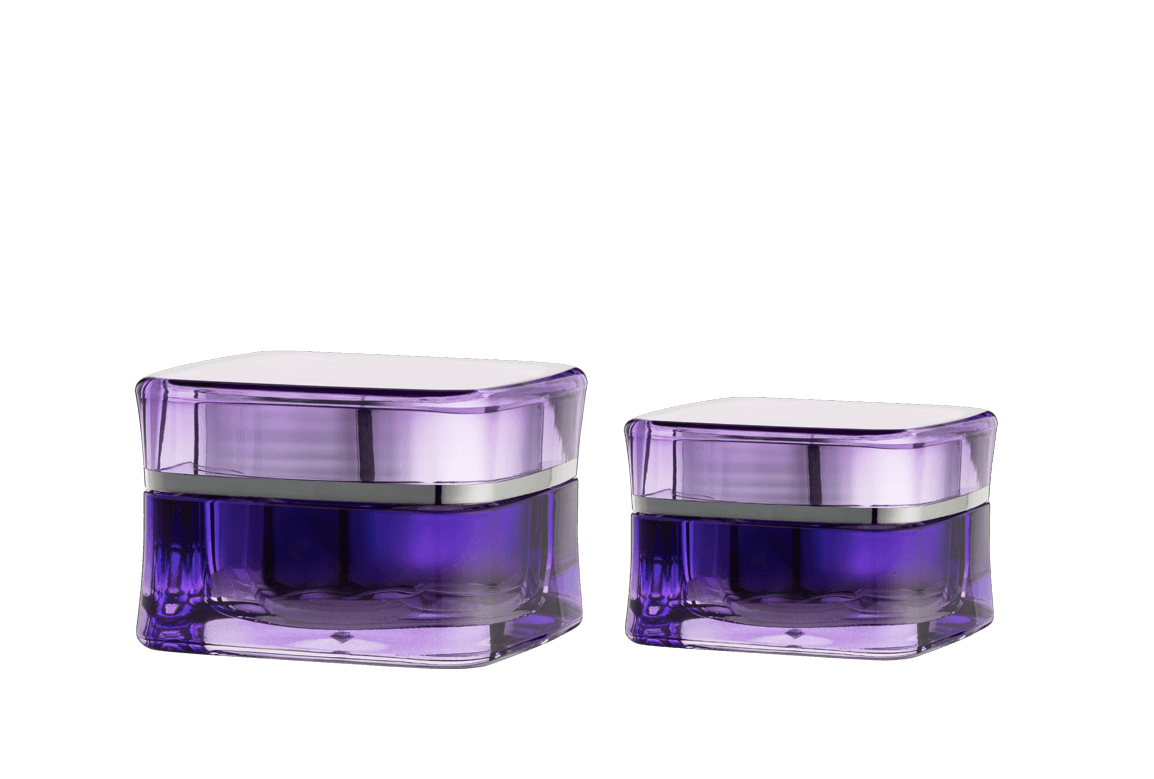

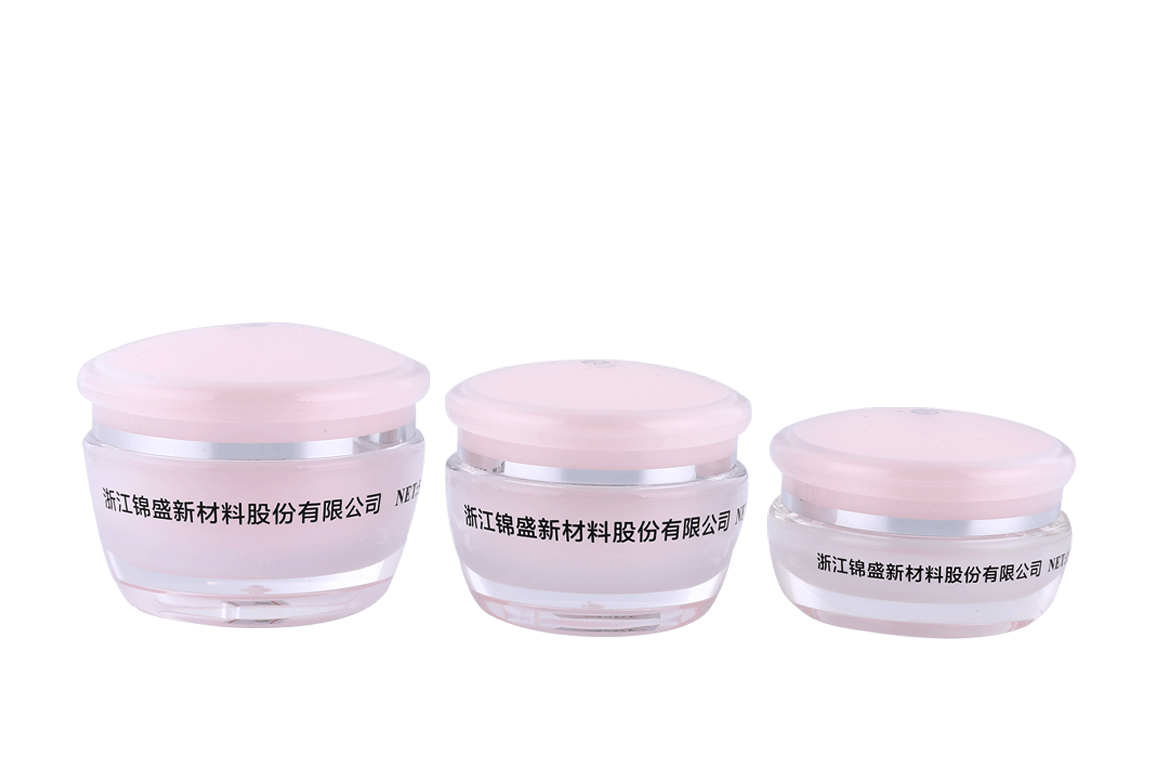

Acrylic (PMMA): As a composite material, acrylic is often used for the outer layer of high-end cosmetic bottle suits due to its transparency and substantial feel. It not only enhances the visual appeal of luxury but also provides additional physical protection, enhancing the robustness of the bottle suit.

2. Sealing Design: Key to Isolating the Internal and External Environments

Sealing is crucial for preventing product deterioration. Any minor leaks or air infiltration can lead to oxidation and bacterial growth.

Bottle Cap and Finish Structure: Threaded, snap-on, and press-on caps are three common sealing methods. High-end bottle suit caps typically feature precision threads to ensure a tight fit, preventing liquid spillage and air ingress. Some bottle caps have an additional PE or silicone gasket inside, creating a double seal and further enhancing leak-proofing.

Pump Head and Sprayer: For lotions and spray products, the quality of the pump head and sprayer is crucial. A high-quality pump head should feature a backflow prevention design to prevent air from entering the bottle through the discharge port after the product is pumped out. A fine atomizer nozzle ensures even product distribution, reducing waste while maintaining a sealed seal.

Airless Pump Bottle: This is a typical application in high-end cosmetic bottle suits. Airless pump bottles utilize a vacuum mechanism to force the contents out of the bottle via the upward movement of a piston, preventing air from entering the bottle and contacting the product. This design is particularly suitable for products containing easily oxidizable or preservative-free natural organic ingredients, fundamentally eliminating the risk of oxidation and microbial contamination, significantly extending the product's shelf life.

3. Production Process and Quality Control: Ensuring Purity from the Source

Even the best design requires rigorous production processes.

Dust-free Production Environment: Cosmetic bottle suits are typically produced in a Class 100,000 dust-free workshop. All production personnel are required to wear professional dust-proof clothing to prevent contamination of the bottles by particles such as dust and hair. A dust-free environment is the first step in ensuring bottle cleanliness and eliminating microbial contamination at the source.

Injection molding and blow molding: During the injection molding and blow molding processes, extremely high mold precision is required. Precision molds ensure uniform bottle wall thickness and precise dimensions, ensuring a perfect fit between the cap and the bottle neck. Any slight dimensional deviation can result in a poor seal and compromise product quality.

Sterilization: Prior to filling, all bottles are sterilized using UV or ozone. This physical sterilization method leaves no chemical residue and effectively kills bacteria and mold inside and outside the bottle, providing a sterile environment for subsequent filling.

Chinese

Chinese España

España Italia

Italia Le français

Le français