PETG (modified polyethylene terephthalate) is an amorphous copolyester with high transparency, good toughness, and superior processing properties. When used in cosmetic bottles and jars, PETG offers both aesthetics and functionality. Its high surface finish and moderate mechanical strength make it a popular choice for packaging high-end skincare, makeup, and personal care products. Since cosmetic bottles and jars often require caps made of various materials, the compatibility of PETG with common cap materials such as PP (polypropylene) and PE (polyethylene) has become a key focus in the industry.

Compatibility of PP Caps with PETG Jars

PP, with its low density, strong chemical stability, and excellent heat resistance, is widely used in cosmetic bottle caps. When paired with PETG jars, PP caps maintain lightweight and cost advantages. PETG's hardness and surface rigidity complement PP well, ensuring a secure seal when screwed or snapped together. In screw-on cap designs, the threads of the PETG can body and the PP cap provide a stable fit, preventing slippage or loosening. Furthermore, the transparency of PETG combined with the versatile coloring of the PP cap can meet the aesthetic requirements of various brands, enhancing the overall packaging quality.

PE Cap and PETG Can Combination

PE is known for its flexibility and excellent chemical resistance and is commonly used in components such as lotion pumps, inner plugs, and sealing gaskets. When combined with a PETG can body and PE cap, the flexible PE material enhances the seal and reduces the loss of volatile ingredients, making it particularly suitable for cosmetic formulations containing fragrances or highly volatile solvents. The rigid PETG bottle mouth complements the elasticity of the PE cap, enhancing the overall sealing reliability of the package. Furthermore, PE's corrosion resistance makes it suitable for formulations with strong acidic or alkaline ingredients, ensuring the stability of the contents together with the PETG can body.

The Impact of Different Materials' Thermal Expansion Coefficients

PETG, PP, and PE exhibit certain differences in their thermal expansion coefficients. PP and PE typically have higher coefficients of thermal expansion than PETG. Under high or low temperature conditions, the materials may contract and expand at different rates. Improper design can lead to looseness or overtightening between the cap and the jar. To avoid these issues, the industry typically optimizes thread structure, adds sealing gaskets, or adjusts the thickness of the bottle neck to compensate for the thermal expansion difference. During the molding design phase, the compatibility of the PETG jar with the PP or PE cap under storage and transportation conditions should be fully considered.

The Impact of Processing Technology on Compatibility

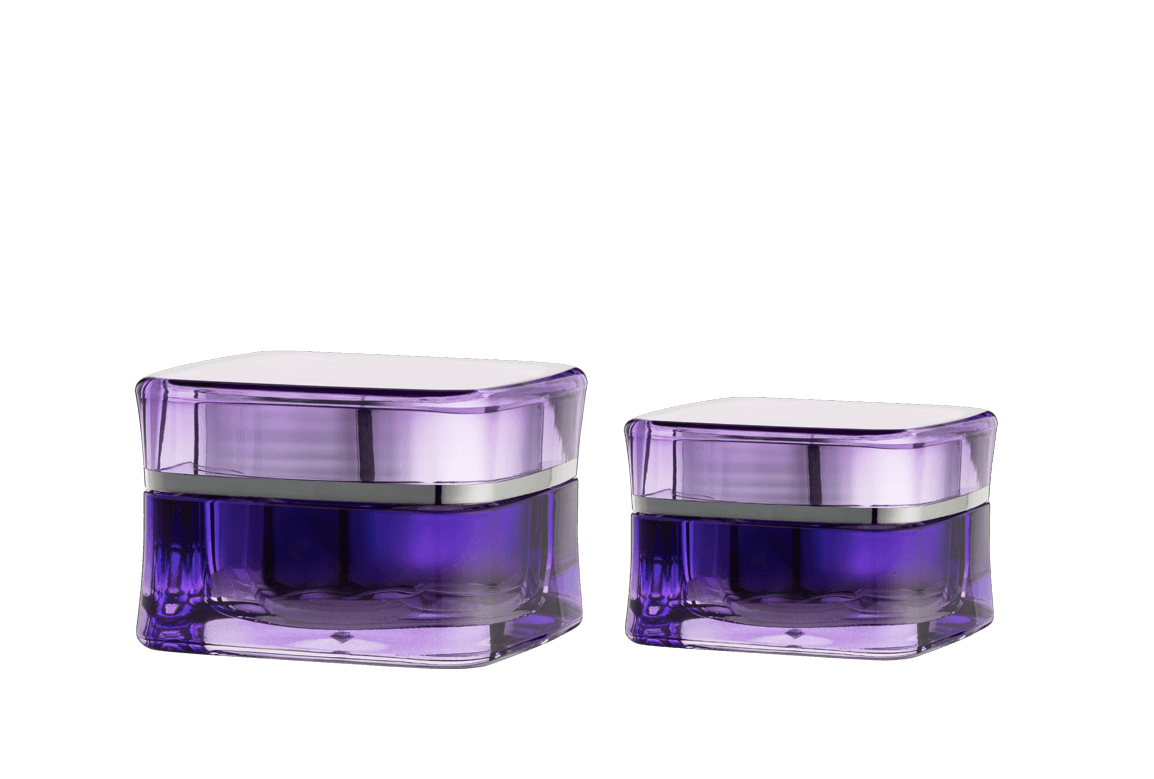

PETG cosmetic jars are often injection molded or blow molded, resulting in high dimensional accuracy at the neck, making them ideal for compatibility with caps made of various materials. PP and PE caps also offer excellent injection molding performance, achieving high dimensional accuracy and aesthetic quality. By strictly controlling mold tolerances and injection molding parameters, the precision fit between the PETG jar and the PP or PE cap can meet industry standards. For products requiring a high-end appearance, the cap can be electroplated, painted, or hot-stamped to create a contrasting visual effect with the transparent PETG jar.

Chemical Compatibility and Safety

Cosmetic formulas often contain surfactants, alcohols, oils, and acids and bases. PETG inherently possesses excellent chemical resistance and is not easily corroded by these common ingredients. PP and PE also possess excellent chemical stability and are less likely to react when exposed to different formulations. The combination of PETG with PP and PE ensures long-term stability of the contents, preventing discoloration, cracking, or seal failure caused by material incompatibility.

Chinese

Chinese España

España Italia

Italia Le français

Le français