When developing a new packaging product, the first consideration is the choice of materials. The selection principles of cosmetic packaging materials are as follows:

1.1 Whether the raw material comes from the finished packaging material itself, and whether the loaded raw material will interact with the plastic material of the packaging material.

1.2 From the perspective of market demand, the market demand can be divided into three grades of packaging: medium, high and low for reasonable selection.

1.3 For the function of the packaging material itself, such as sealing parts, soft rubber is mostly used. Cosmetic packaging

1.4 According to the company's own situation, the same packaging material can meet the design requirements. Sometimes there are several kinds of materials, the price is not the same. However, it depends on the company itself. Sometimes, it's not necessarily cheap for the best, but it's important to communicate and cooperate with suppliers.

2. Choose a reasonable structure

The structural development of packaging materials does not mean that the more complex the better; on the contrary, the simpler the structure, the better, as long as it can meet all functional requirements. The structure is simple, the mold is simple, the assembly is simple, and there are few problems.

3. Simplify the mold structure

The development of packaging material structure must be designed under the condition of mold opening. It is very important to understand the mold structure and molding method. Don't design for a long time, it's embarrassing to open a mold without a meeting.

The mold can be opened, and the mold structure should be simplified. Simplify the principle and minimize compensation. Cosmetic packaging

4. Control the cost of packaging materials

This is also part of the core of the entire packaging material, and the cost determines the company's profit, which is for the pure plastic packaging material factory.

4.1 On the basis of meeting the same conditions, try to choose materials with low prices. Cosmetic packaging

4.2 On the basis of meeting the appearance requirements, reduce the number of accessories.

4.3 Simplify the product structure so that each structure is useful. Thus saving the cost of the mold.

4.4 Packaging materials should be properly matched.

4.6 According to the appearance requirements, choose a reasonable, high-suburban, low-cost surface treatment method, such as whether the suburban fruit can be directly treated on the surface of the mold.

4.7 There should be a set of standard controls for the development progress of new packaging materials to prevent unnecessary mistakes and delay delivery.

4.8 If allowed, try to use the existing mature products in the city to cooperate with the development. For example, choosing the commonly used dental braces and preform products on the market is of great help in reducing the cost of the entire package and promoting the development progress.

What should we pay attention to when choosing cosmetic packaging materials?

1. Quality problems of packaging materials

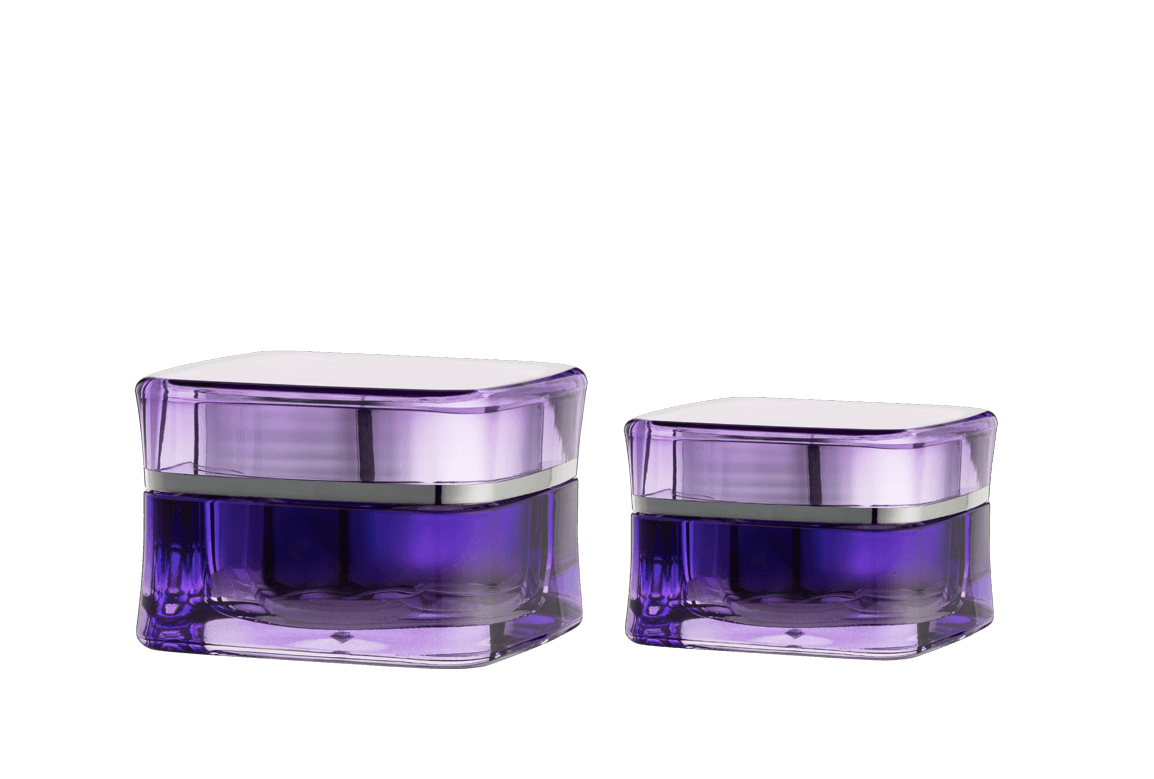

In the OEM of cosmetics, there are many packaging materials, such as boxes, bottles, bags, etc. For these mass-produced bottles, bottles and cans, if the quality of packaging materials is not up to standard, problems such as cracks, poor sealing, easy side leakage, and excessive deviation of packaging materials will occur during transportation. Cosmetic packaging

2. The problem of incomplete packaging materials

Incomplete matching of packaging materials is a common problem in cosmetic OEMs. Because many cosmetics are not satisfied by a single bottle or box, such as a cream bottle consists of a bottle, a lid, a hand pad, a box, a holder, a label, etc. There are too many small parts, and it is easy to miss a part in the production process.

3. The problem of false packaging ability

Because the capacity of cosmetic containers is very different from the marked specifications, for example, the standard size of some perfume bottles is 50ML, while the actual packaging capacity is 30ML or 70ML. Cosmetic packaging

4. Product packaging format

The format of cosmetic packaging materials does not conform to national standards. For example, the full name of the cosmetic manufacturer, production license, hygiene license, cosmetic standard, implementation standard and QS are not clearly marked on the product packaging; imported products do not contain Chinese descriptions.

Cosmetics names, specifications, and product packaging are prone to mismatch, so care must be taken when packaging on the production line.

Check whether the printed words and patterns of the packaging materials are ambiguous; whether the words, patterns and design drafts are consistent; whether the product names and specifications are clear.

Chinese

Chinese España

España Italia

Italia Le français

Le français