With the booming global beauty market, high-end cosmetic bottle suits have become a crucial vehicle for brands to showcase their value, quality, and uniqueness. However, the prevalence of counterfeit and substandard products not only severely damages brand reputation but also threatens consumer health and safety. Therefore, incorporating anti-counterfeiting technology into the design and production of high-end cosmetic bottle suits has become a critical component of brand safeguarding.

1. Physical Anti-Counterfeiting Technology: From Materials to Structure

Physical anti-counterfeiting technology uses specialized materials, processes, or structural designs to make the bottle suit inherently difficult to replicate.

Specialty Inks and Coatings: Printing with ultraviolet (UV) fluorescent inks or temperature-sensitive inks. These are invisible to the naked eye under ordinary light, but reveal the brand logo or specific pattern under specific light sources (such as the UV light in a currency detector pen). Temperature-sensitive inks change color with temperature, adding interest and recognition.

Laser anti-counterfeiting and holograms: These are among the most common anti-counterfeiting methods used in high-end products. Holographic anti-counterfeiting labels applied to bottles or packaging utilize optical principles to create multi-dimensional, dynamic images. These holograms are often difficult to accurately replicate and leave a mark once removed, effectively preventing secondary use.

Microengraving and microporous technology: Invisible to the naked eye, microscopic text or patterns are incorporated into the mold of the bottle or cap. These microengravings require high-power magnification to see clearly, and the production process is extremely precise, making them extremely difficult to replicate. Microporous anti-counterfeiting technology uses laser drilling to create a microscopic code on the surface of the bottle or cap that is invisible to the naked eye and can only be read using specialized equipment.

Specialized seal designs: Utilize a one-time destructible seal, such as a "tear-off" label or a special anti-tamper feature on the bottle cap. Once the bottle is opened, the seal is destroyed, alerting consumers to product use or tampering, ensuring they are purchasing a brand-new, authentic product.

2. Digital Anti-Counterfeiting Technology: Giving Products an "Identity Card"

Digital anti-counterfeiting technology assigns each product a unique digital identity, enabling full traceability and verification from production to consumption.

QR Codes and Barcodes: Unique QR codes are printed on bottles or packaging. Consumers simply scan them with their phones to access the brand's official verification page, where they can check product information such as the production batch, production date, and expiration date. Furthermore, a backend data system records the location and time of each query. If the same code is frequently queried within a short period of time, the system will issue an alert, effectively combating counterfeiting.

NFC (Near Field Communication) Chips: NFC chips are embedded in the bottle cap or bottom of the bottle. Consumers simply hold their NFC-enabled smartphone near the bottle to automatically read the encrypted information within the chip. Compared to QR codes, NFC technology eliminates the need for scanning, making the experience more convenient. Furthermore, the encrypted information is more difficult to copy or tamper with, providing enhanced security.

RFID (Radio Frequency Identification) Technology: Similar to NFC, RFID tags can be read contactlessly. This technology is particularly important in supply chain management. Brands can use handheld RFID readers to inventory and verify the authenticity of large quantities of products in a short period of time, effectively tracking the flow of each product and eliminating counterfeit goods at the source.

3. Comprehensive Anti-Counterfeiting Technology: Multiple Safeguards

High-end cosmetic bottle suits often utilize a combination of multiple anti-counterfeiting technologies, creating an impenetrable "security fortress."

For example, a high-end skincare bottle suit might utilize the following technologies:

Bottle: Made of glass with a special optically variable coating.

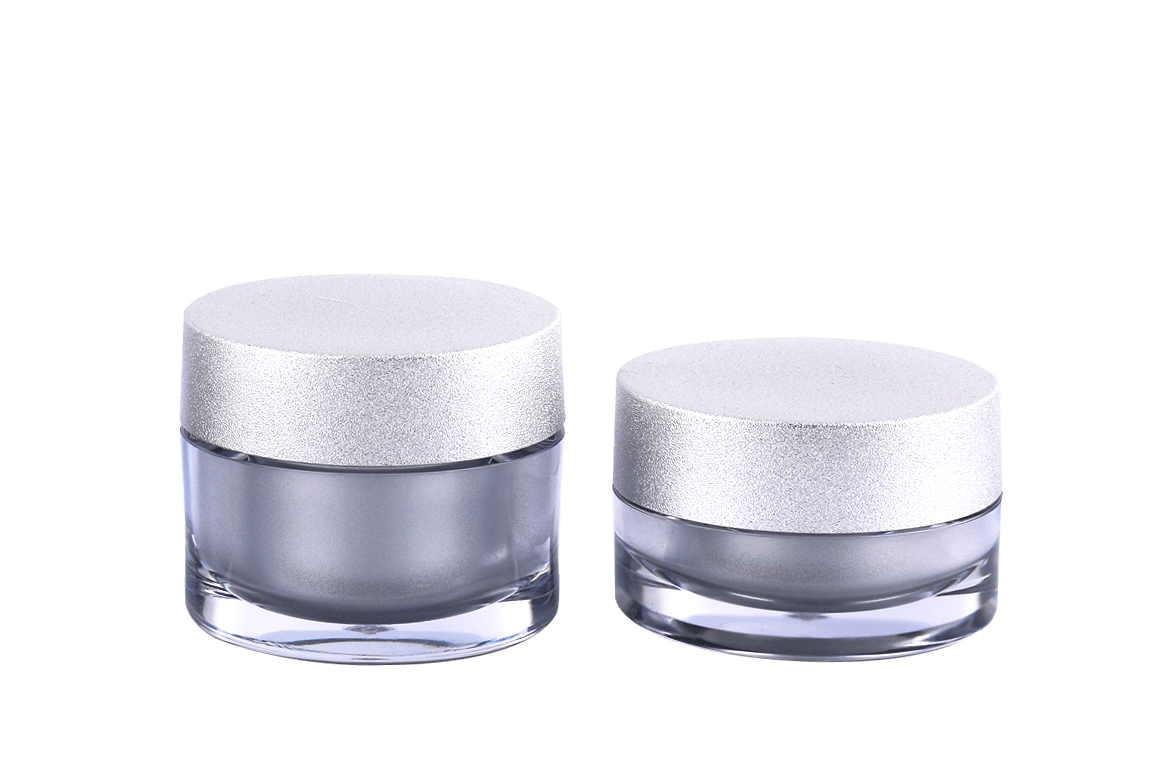

Bottle cap: Embedded with an NFC chip and micro-engraved with the brand logo.

Outer box: Attached with a one-time destructible holographic anti-counterfeiting label and a printed QR code.

This combination of physical and digital security not only enhances anti-counterfeiting security but also enhances the interactive experience between consumers and the product. Consumers can quickly confirm product authenticity through intuitive visual changes and convenient mobile phone verification, thereby building trust in the brand and reducing purchase risks.

Chinese

Chinese España

España Italia

Italia Le français

Le français