Cosmetic packaging is not only about beauty, but also directly affects the stability, user experience and market competitiveness of the product. The application of cosmetic bottle suits in different types of products such as lotions, essences, water, creams, etc. requires matching appropriate packaging materials according to the physical properties, chemical composition and usage scenarios of the contents. The following is a detailed analysis of the professional requirements for bottle set materials based on the four common types of cosmetics.

Packaging material requirements for lotion cosmetics

Lotion products are relatively thin and have strong fluidity. The ingredients usually contain oils, emulsifiers, water and active substances. The packaging materials must have the following characteristics:

High chemical stability: The oily components in the lotion may react with certain plastic materials. Commonly used materials such as HDPE (high-density polyethylene) and PET (polyethylene terephthalate) show good compatibility.

Good oxygen barrier performance: To prevent the active ingredients from being oxidized, it is recommended to use a multi-layer bottle structure with an oxygen barrier layer, such as EVOH composite bottles or vacuum pump bottles.

Leak-proof and anti-seepage design: Due to its strong fluidity, the bottle mouth and pump head should be designed with good sealing to prevent the lotion from leaking or the bottle from being contaminated during use.

Considering both touch and pressure resistance: Consumers need a certain degree of bottle softness when using it. PE hose type or PP medium-hard bottle can be selected to ensure smooth squeezing.

High-precision requirements for packaging of essence cosmetics

Essence is usually a high-concentration, high-activity product, and has the most stringent requirements on packaging materials. Its characteristics determine that the Cosmetic Bottle Suit must take into account both chemical protection and precision control:

High barrier materials: To avoid oxidation and degradation of ingredients, it is recommended to use glass bottles (especially amber glass), AS, PETG and other high-stability materials.

Vacuum pump system or dropper design: Using a vacuum pump can prevent air from entering to the greatest extent and maintain product activity; the dropper design can accurately control the amount of each use, which is common in high-end essence products.

Corrosion resistance and inertness: Essences containing acid or multiple active substances need to be matched with inert stainless steel pump heads or anti-corrosion liners, such as PP or PE liners + metal shells.

Small-capacity design trend: In order to reduce pollution and enhance freshness, small-size bottles such as 15ml and 30ml are usually used, which puts higher requirements on packaging accuracy and sealing.

Selection criteria for packaging materials for water-based (toner/lotion) cosmetics

Toner products use water as the main ingredient, have low viscosity, and are easy to evaporate. The requirements for packaging materials are as follows:

Anti-leakage design is the key: Due to the high fluidity of the product, structures such as screw caps with gaskets, pressure pump bottles or rotary spray pumps should be used to prevent leakage during transportation and use.

Lightweight and transparent materials: PET materials are mostly used, which have good transparency and cost control advantages, and are easy to show the true color of the product.

Antibacterial and cleanliness requirements: The bottle body must have good cleanliness to avoid the growth of microorganisms. EO sterilization or aseptic filling and closed systems can be considered.

Hydrolysis resistance is preferred: Long-term storage of lotion will cause hydrolysis of plastic materials. Choosing PP or high-grade PET will help extend the shelf life of the product.

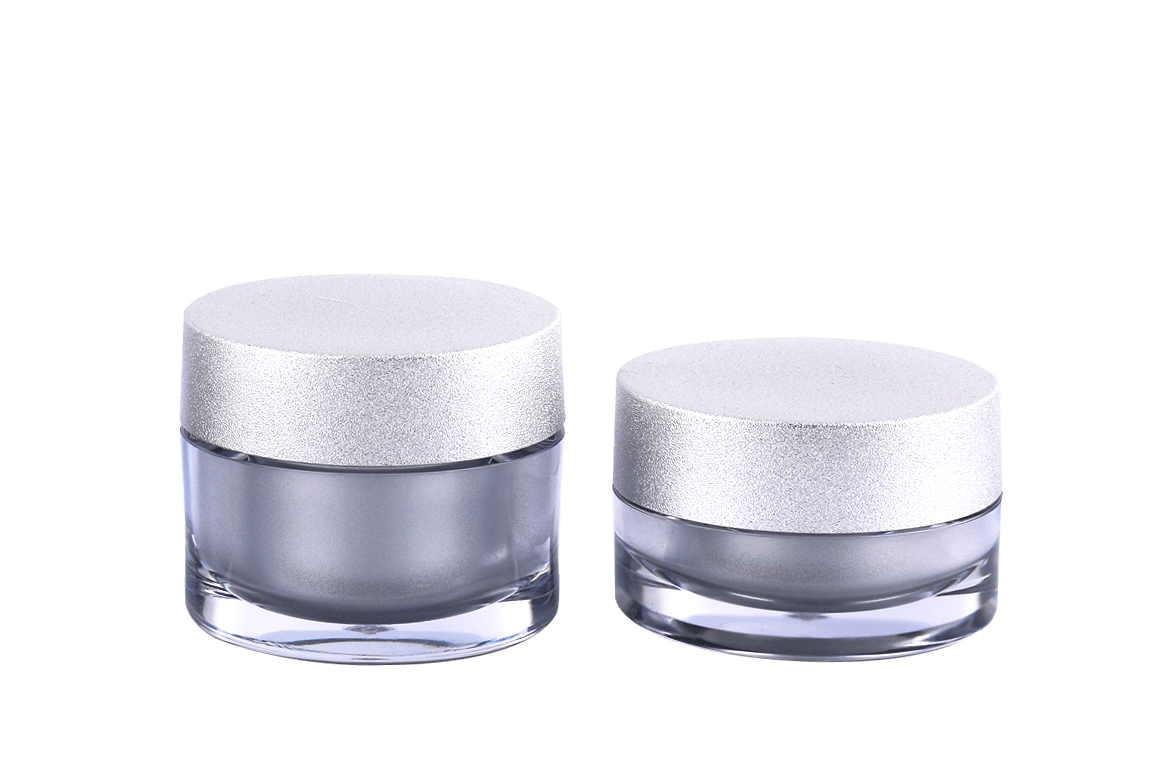

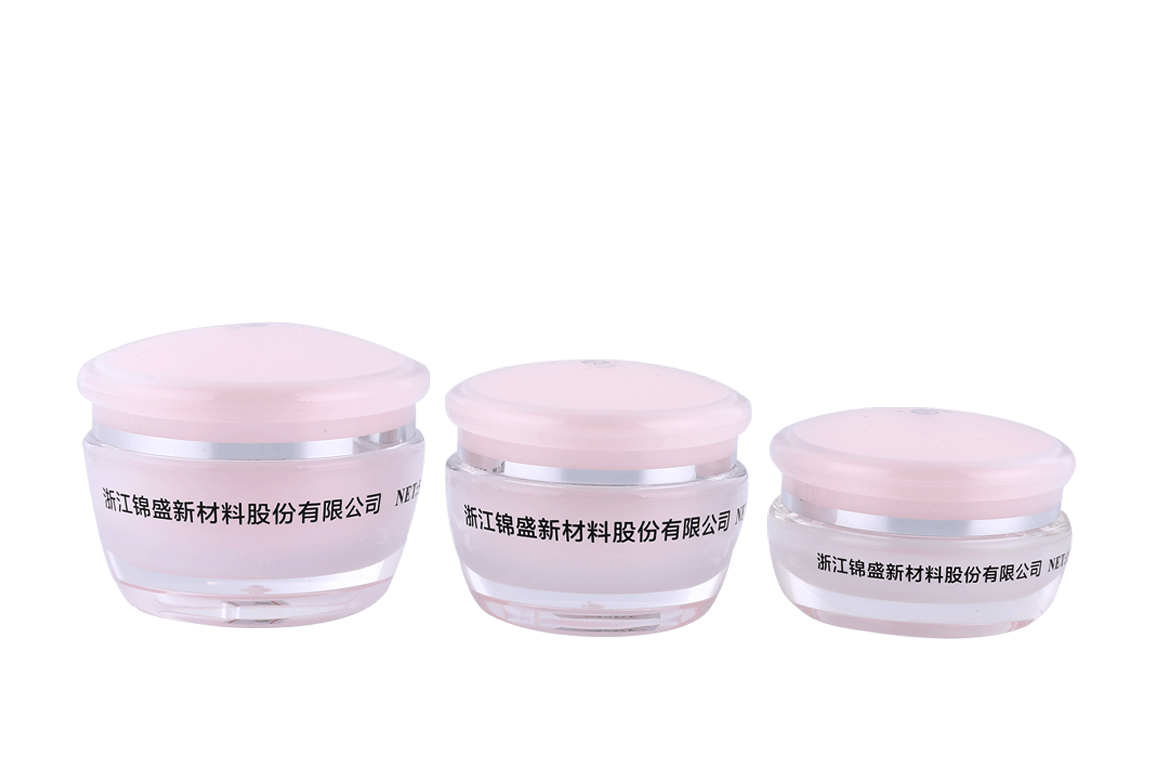

Special requirements for container sealing and anti-pollution of face cream products

Face cream products are usually thick in texture and contain more oils and emulsifiers, which puts forward the following requirements for packaging materials and structures:

High-sealing packaging structure: The use of screw-cap wide-mouth bottles or double-closed structures of inner cover + outer cover can effectively prevent air and dust from entering and maintain the stability of the cream.

High-quality liner materials: The liner needs to be highly compatible with the contents to avoid plasticizer migration or odor adsorption. Commonly used materials include PP, SAN, PETG, etc.

Compatibility with extrusion and scraping tools: Many brands come with a small spoon, and the inner wall of the package needs to be smooth and easy to scrape; at the same time, the outer bottle often uses hard materials such as acrylic and ABS to enhance the appearance and durability.

Requirements for anti-deformation and temperature resistance: Frost is often used in winter and dry climates, and requires higher cold resistance and stability of the packaging, especially the shape should remain unchanged under temperature fluctuations during transportation.

Chinese

Chinese España

España Italia

Italia Le français

Le français