What is PETG material?

PETG is a modified polyester material, which is a copolymer of polyethylene terephthalate glycol (PETG). PETG material has high transparency, high impact resistance, good processing performance and excellent chemical resistance, and is widely used in high-end cosmetic packaging, medical devices, food containers and other fields.

PETG is more flexible and has better thermal stability than ordinary PET, and has excellent gloss and durability. It is a common high-performance plastic choice in the manufacture of cosmetic bottles and jars.

The main molding process of PETG cosmetic bottles

Injection Molding

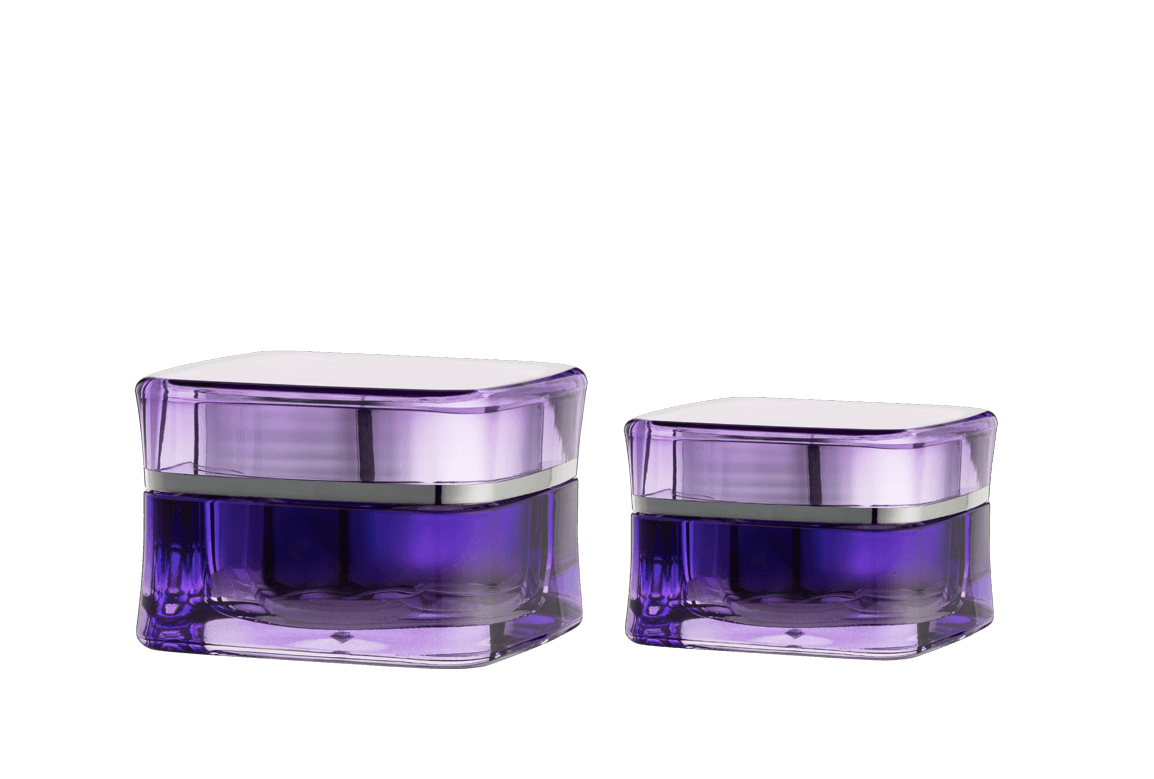

Injection molding is a widely used manufacturing method in PETG cosmetic bottles, especially for thick-walled and high-precision bottle and jar structures.

The process principle is to heat and melt the PETG particles, and then inject them into the metal mold under high pressure to cool and shape them. It is suitable for PETG cosmetic jars with thick caps, bottoms, and walls or with complex texture decorations.

Advantages:

High surface precision and strong plasticity

High gloss mirror effect can be achieved

Supports complex modeling and LOGO embossing

Suitable for mass automated production

Disadvantages:

High mold cost

High cost for small batch customization

High requirements for equipment temperature control, prone to stress cracks

Injection molded PETG bottles are suitable for high-end face creams, eye creams, and paste cosmetics packaging, and products with higher requirements for brand vision and feel.

Extrusion Blow Molding

Extrusion blow molding is mainly used for the manufacture of small and medium-sized PETG bottles. The molten PETG is extruded into a tubular blank through the die head, and then blown to the inner wall of the mold by airflow, and cooled to form a hollow bottle.

Advantages:

Suitable for manufacturing thin-walled, hollow PETG containers

High molding efficiency and low cost

Suitable for automated continuous production lines

Various bottle capacity and shape designs are flexible

Disadvantages:

Relatively low wall thickness control accuracy

Not suitable for products with complex structures and high transparency requirements

It is difficult to achieve high-end appearance processing

This process is widely used in mid-range product packaging such as facial cleansers, shower gels, shampoos, etc. that require general appearance refinement.

Injection Stretch Blow Molding

Injection Stretch Blow Molding is a high-end molding process for manufacturing PETG cosmetic bottles, especially for product packaging with extremely high transparency requirements, such as essences, skin care water, etc.

The process includes two stages: first, the preform is injected, then the preform is heated and stretched into the mold, and then it is blown into shape by high-pressure gas, and finally cooled and shaped.

Advantages:

High transparency and outstanding gloss

Uniform wall thickness and high consistency

Good bottle strength and excellent resilience

Suitable for high-end brand packaging applications

Disadvantages:

Long production cycle

Complex mold design and high cost

Strict requirements on raw material quality and process parameters

PETG bottles made by injection stretch blow molding have a glass-like transparency and are an ideal choice to replace glass bottles.

Precautions in the molding process of PETG materials

High temperature control accuracy

PETG has a high viscosity in the melting stage, and the melting temperature needs to be strictly controlled (recommended at 220~250°C) to prevent material decomposition or insufficient fluidity.

High requirements for mold surface polishing

In order to achieve high gloss and high transparency visual effects, the mold cavity surface needs to be mirrored to avoid mold defects affecting the appearance.

Avoid residual stress during molding

PETG is sensitive to stress, and the cooling rate needs to be balanced to prevent stress cracks from forming during subsequent transportation or use.

Drying treatment cannot be omitted

PETG material has strong hygroscopicity and needs to be fully dried before processing. It is recommended to dry it at 65°C for more than 4 hours to reduce defects such as bubbles and silver streaks.

Chinese

Chinese España

España Italia

Italia Le français

Le français