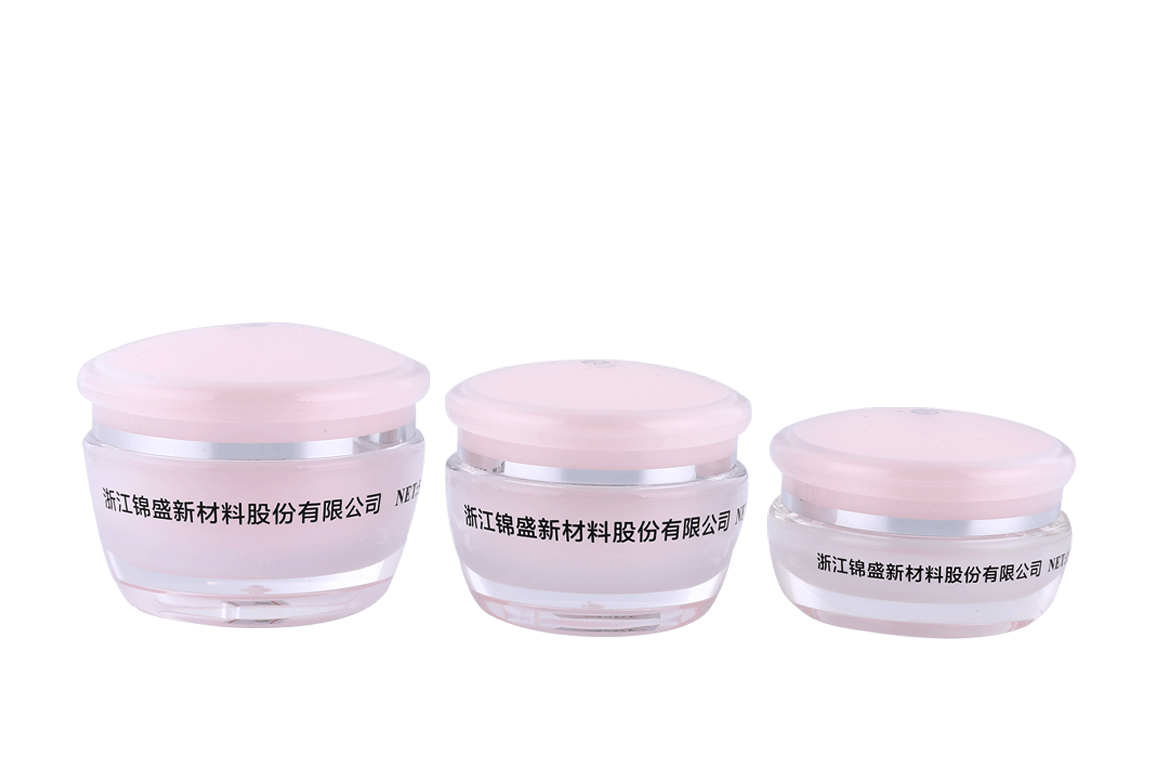

PMMA as the Core Material for Ice Crackle Acrylic Bottles

Acrylic Ice Crackle Lotion Bottles are primarily manufactured using PMMA (Polymethyl Methacrylate), a thermoplastic material widely recognized for its high transparency, excellent surface gloss, and strong aesthetic appeal. PMMA offers a light transmittance rate exceeding 90 percent, allowing the ice crackle pattern to appear deep, three-dimensional, and visually refined. This material provides a glass-like appearance while maintaining lower weight and greater design flexibility, making it a preferred choice for premium cosmetic and skincare packaging.

Optical Grade PMMA for High-End Visual Performance

Optical grade PMMA is frequently used in luxury Acrylic Ice Crackle Lotion Bottles. This material grade is characterized by extremely low impurity levels, uniform molecular structure, and minimal internal stress. These characteristics enhance light refraction within the crackle layers, producing a crystal-clear and multi-dimensional ice crackle effect. Optical grade PMMA is commonly applied in prestige skincare brands, anti-aging lotion packaging, and high-value cosmetic lines where packaging appearance plays a critical role in brand perception.

Impact-Modified PMMA for Enhanced Durability

Certain Acrylic Ice Crackle Lotion Bottles utilize impact-modified PMMA to improve resistance to cracking and breakage. This material is formulated by blending PMMA with elastomeric modifiers that increase toughness without significantly reducing transparency. The improved impact resistance helps protect the outer crackle shell during transportation, handling, and daily consumer use. This type of acrylic material is particularly suitable for larger-capacity lotion bottles or export-oriented cosmetic packaging requiring higher mechanical reliability.

PMMA for Double-Wall Ice Crackle Structures

Double-wall construction is a defining feature of many Acrylic Ice Crackle Lotion Bottles. In this structure, the outer layer is typically produced using PMMA optimized for crackle formation, while the inner bottle may use a different PMMA formulation focused on chemical stability and product safety. The outer PMMA layer emphasizes hardness and visual depth, while the inner layer prioritizes compatibility with cosmetic formulations. This material differentiation supports long-term performance while maintaining a premium exterior appearance.

Injection-Grade PMMA for Precision Manufacturing

Injection-grade PMMA is widely applied in the production of Acrylic Ice Crackle Lotion Bottles due to its stable melt flow behavior and dimensional accuracy. This material grade supports complex mold designs, enabling precise control of bottle shape, wall thickness, and crackle pattern distribution. Uniform shrinkage rates during cooling help maintain structural consistency and reduce deformation risks. Injection-grade PMMA also performs well in secondary processes such as polishing, vacuum metallization, spraying, and silk-screen printing.

Chemical-Resistant PMMA for Active Skincare Formulations

Some Acrylic Ice Crackle Lotion Bottles are designed to contain formulas with active ingredients, including mild acids, alcohol components, or botanical extracts. For these applications, chemical-resistant PMMA is selected to reduce the risk of stress cracking, clouding, or surface degradation. This material type offers enhanced resistance to cosmetic ingredients commonly used in functional skincare products, making it suitable for dermocosmetic, professional skincare, and medical-grade lotion packaging.

PMMA Formulations Developed for Ice Crackle Effects

Specialized PMMA formulations have been developed specifically to enhance ice crackle visual effects. These materials are engineered to respond predictably to controlled temperature changes or post-molding treatments, allowing the formation of natural-looking, irregular crackle patterns. The internal stress distribution of the acrylic is carefully managed to achieve consistent crackle depth and density across production batches. This type of PMMA supports brand requirements for repeatable aesthetics and high visual standards.

Eco-Modified and Sustainable PMMA Materials

Sustainability considerations have influenced material selection in Acrylic Ice Crackle Lotion Bottles. Some manufacturers incorporate eco-modified PMMA or partially recycled acrylic materials into their packaging solutions. These materials are designed to maintain clarity, mechanical strength, and crackle appearance while reducing reliance on virgin petrochemical resources. Advances in material purification and compounding technology allow sustainable PMMA options to meet the visual expectations of premium cosmetic packaging.

Influence of Acrylic Material Selection on Product Positioning

The choice of PMMA type directly affects the appearance, durability, and market positioning of Acrylic Ice Crackle Lotion Bottles. High-transparency and optical-grade PMMA materials align with luxury branding and high-end product lines. Impact-modified and chemical-resistant PMMA materials support functional skincare products and long-term consumer use. Specialized crackle-grade PMMA enhances decorative value and brand differentiation. Each material configuration contributes to the perceived quality and lifecycle performance of the final packaging.

Role of Material Engineering in Premium Cosmetic Packaging

Advanced material engineering plays a central role in the development of Acrylic Ice Crackle Lotion Bottles. Precise control over PMMA composition, molecular structure, and processing behavior enables manufacturers to achieve consistent crackle patterns, stable bottle structures, and refined surface finishes. The strategic application of multiple PMMA material types within a single bottle design supports both aesthetic excellence and functional reliability, reinforcing the value of acrylic ice crackle packaging in the competitive cosmetic market.

Chinese

Chinese España

España Italia

Italia Le français

Le français