In the Cosmetic Packaging sector, sustainability has shifted from a marketing slogan to a mandatory industry requirement. For brand owners and packaging manufacturers, understanding the differences between PCR (Post-Consumer Recycled plastic) and Virgin Plastic in terms of physical properties, processing technology, and brand value is central to optimizing the supply chain.

Differences in Physical Properties and Structural Stability

Virgin Plastic is refined directly from crude oil, resulting in a complete and uniform molecular chain structure. When manufacturing Airless Bottle systems, virgin plastic provides excellent Mechanical Strength and Stress Crack Resistance.

In contrast, PCR materials have undergone cycles of consumer use, recovery, cleaning, and secondary pelletizing.

Molecular Weight Distribution: After multiple rounds of thermal processing, the polymer chains in PCR may undergo partial degradation. This typically results in a Tensile Strength that is 85% to 95% of that found in virgin materials.

Hardness and Toughness: In the design of all-plastic vacuum pumps, the Rebound Force of PCR materials may be slightly inferior to virgin resin. This requires engineers to fine-tune wall thickness and support structures during mold design to compensate for material performance fluctuations.

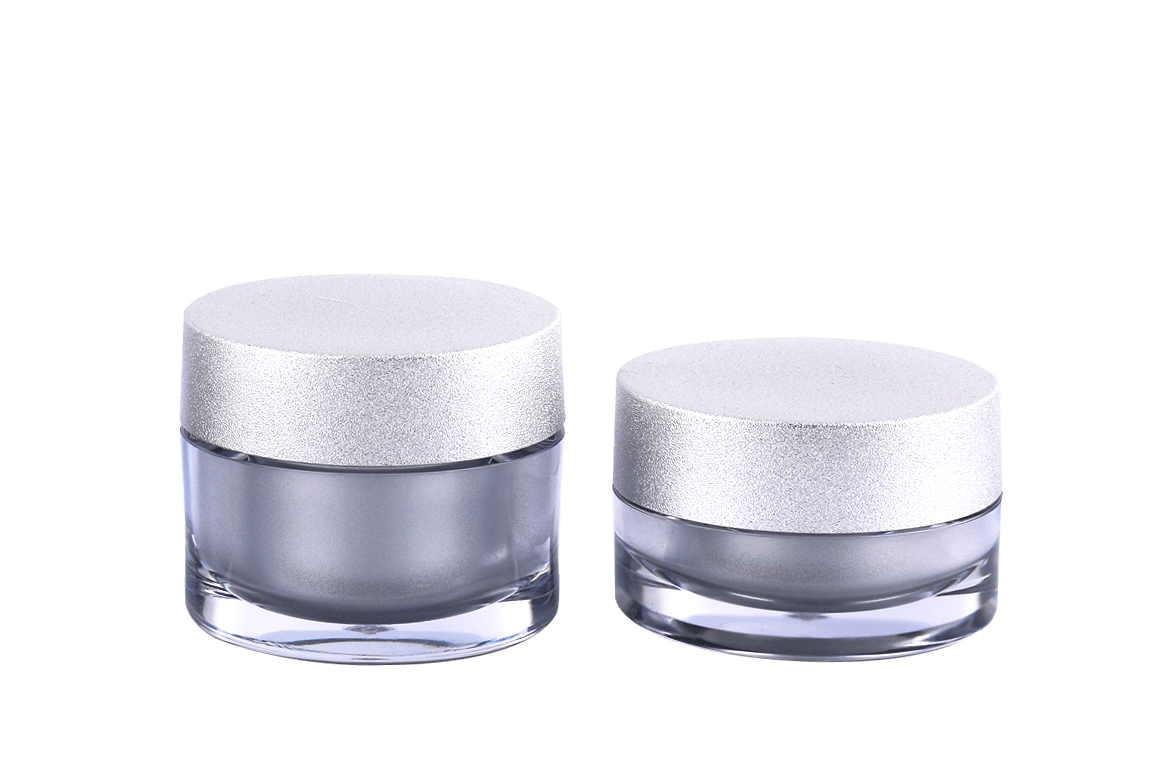

Aesthetics and the Redefinition of Visual Standards

For high-end brands pursuing ultimate visual effects, Aesthetics serves as the most intuitive standard for distinguishing between the two materials.

Transparency: Virgin Plastic (such as PET or PP) can achieve crystal-clear transparency. PCR materials, due to diverse feedstocks, usually exhibit a slightly yellowish or milky white tint even after fine filtration, and may contain minute impurities known as "black spots."

Color Consistency: Virgin plastic allows for precise reproduction of Pantone colors without deviation. PCR materials face Batch-to-batch variation risks due to raw material sources. Consequently, brands using PCR packaging often choose to add Masterbatch for solid color coverage or utilize the "recycled texture" as a deliberate visual language for eco-friendly design.

Compatibility Testing and Safety Assurance

The Compatibility Test is the decisive factor in the success or failure of any packaging material.

Impurity Profile: Virgin Plastic possesses extremely high purity with almost zero risk of extractables. PCR materials must pass rigorous Food Grade or equivalent laboratory testing to ensure that no residual harmful chemicals or heavy metals from the recycling process migrate into the skincare formulation.

Barrier Properties: In a Vacuum Bottle, which has high requirements for airtightness, PCR must maintain oxygen and water vapor barrier rates comparable to virgin plastic to ensure the stability of products containing active ingredients like Retinol.

Production Costs and Sustainable Value

From a cost perspective, the market price of PCR is currently often higher than that of virgin plastic.

Processing Cost: The collection, precision sorting, cleaning, and decontamination processes significantly increase Supply Chain costs. Furthermore, the Melt Flow Index of PCR during injection molding may be unstable, leading to slightly higher scrap rates compared to virgin plastic.

Environmental Impact: Utilizing PCR can reduce carbon emissions by approximately 60% and decrease reliance on fossil fuels. Under the ESG (Environmental, Social, and Governance) evaluation framework, this environmental premium significantly enhances a brand's market competitiveness.

Chinese

Chinese España

España Italia

Italia Le français

Le français