The design of premium cosmetic packaging is not merely an pursuit of visual splendor; it is a rigorous combination of material science, product protection, and brand positioning. In the realm of cream and lotion packaging, the Acrylic (PMMA) Double-Wall Structure has become the standard configuration for upscale brands. This structure surpasses traditional single-layer plastic or glass containers by offering unique physical, chemical, and aesthetic advantages.

1. Superior Product Protection Barrier: Enhancing Formula Stability

The core value of the double-wall structure lies in its robust protective capabilities for the internal product.

Thermal Insulation and Temperature Control

Many active ingredients in cream formulas, such as peptides, growth factors, vitamins, and natural extracts, are highly sensitive to temperature fluctuations. Single-layer containers are easily affected by ambient temperature changes.

The double-wall design creates a stable air layer between the outer acrylic shell and the inner cup (usually made of PP, AS, or PE). This air layer acts as a micro-insulator, significantly slowing down the transfer of external temperature (both high and low) to the inner cup. This Thermal Buffering Effect helps keep the cream within a more stable temperature range, minimizing the risk of active ingredient decomposition or deterioration due to thermal shock, thereby extending the product's shelf life.

Moisture Defense and Enhanced Sealing

Double-wall designs typically incorporate a more complex threading and sealing system, making them more effective at resisting external moisture and air penetration. The inner cup operates independently of the acrylic outer shell, reducing the impact of the material's own micro-porosity on the product. This structural design helps maintain the Water Activity balance inside the inner cup, preventing the cream from drying out due to moisture evaporation or becoming diluted due to external moisture ingress, thus ensuring the formula's proper viscosity and homogeneity.

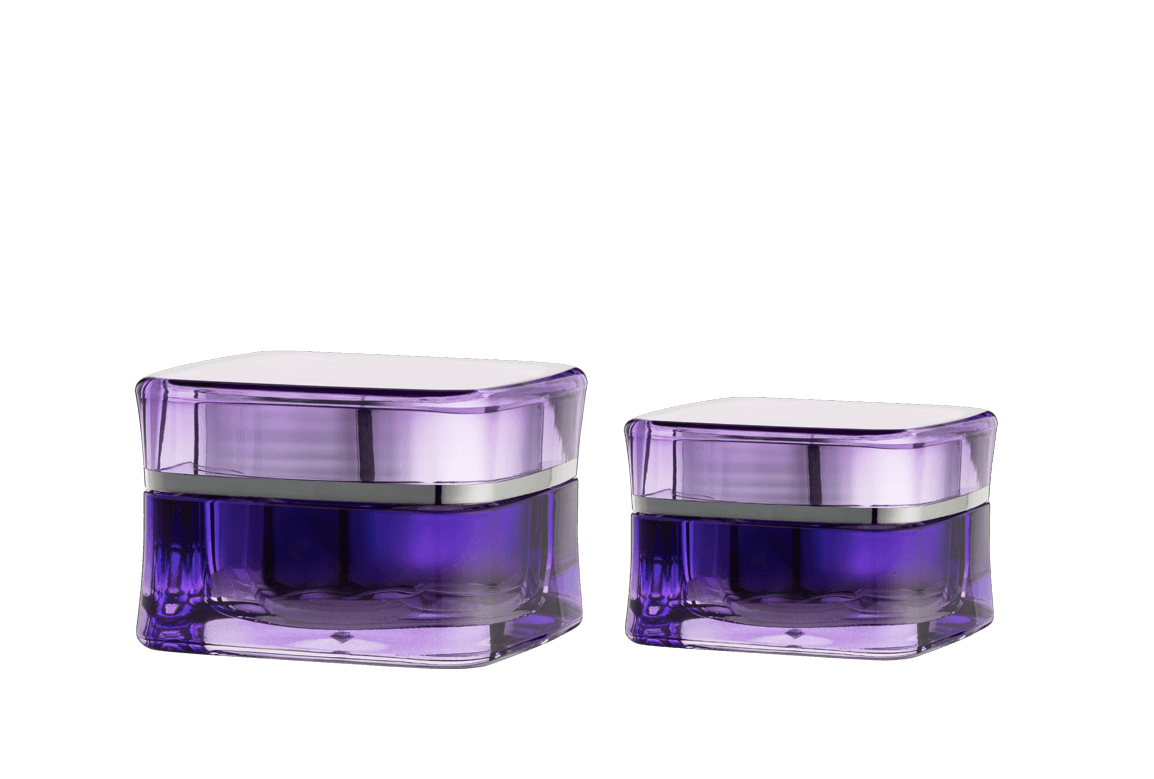

2. Luxurious Visual Experience: Achieving Glass Clarity with Plastic Durability

The acrylic double-wall structure is the optimal solution for the cosmetics industry's pursuit of "glass texture with plastic resilience."

Crystal Clarity and Refractive Effect

The outer layer utilizes high-grade Acrylic (PMMA), which boasts excellent optical properties, comparable to optical glass in transparency and luster. The double-wall design, leveraging the air gap and two smooth surfaces, creates a unique sense of depth and three-dimensionality.

Manufacturers can use the injection molding process to give the acrylic shell a crystal-like Heavy Wall Effect. This heavy, crystalline visual immediately elevates the product to a premium tier, conveying a sense of value and sophistication that perfectly aligns with the market positioning of expensive creams. Furthermore, applying 3D Decoration such as color injection, spraying, or electroplating between the two layers allows for visual depth and complex aesthetic effects that single-layer structures cannot achieve.

Impact Resistance and Shatter-Proof Nature

Despite possessing the appearance of glass, acrylic is fundamentally Polymethyl Methacrylate, which has excellent Impact Resistance.

Unlike fragile glass containers, double-wall acrylic jars are less likely to shatter or chip during transit, handling, and daily use, significantly reducing the risk of product damage in logistics and retail. This durability not only provides safety and convenience to the consumer but also safeguards the brand's quality control reputation. Even if subjected to impact, the outer layer may only crack, and the internal product is protected from leakage or contamination by the secondary barrier of the inner cup.

3. Structural Compatibility and Hygiene Assurance: Customized Inner Cup Design

The double-wall structure allows manufacturers to flexibly select the inner cup material based on the cream's chemical properties and application needs.

Optimizing Inner Cup Chemical Compatibility

The inner cup is in direct contact with the product, making its Chemical Compatibility crucial. For example, formulas containing acidic components or certain essential oils may require the inner cup to be made of high-purity, low-reactivity Polypropylene (PP) or Polyethylene (PE).

In the double-wall structure, the inner cup can be specifically chosen for the best stability with the formula, while the outer layer focuses on providing the premium, aesthetic support structure. This internal and external separation resolves the dilemma that a single material often fails to meet both the requirements for high-end appearance and high chemical stability.

Ease of Filling and Hygienic Handling

The inner cup is often designed to be removable or replaceable. This design simplifies the filling process on cosmetic production lines, as filling only needs to target the inner cup.

For consumers, Refill Pods align with current environmental trends, allowing users to replace the inner cup directly after purchasing a refill, reducing packaging waste. For the brand, this not only provides a sustainable sales model but also ensures that the product the consumer interacts with is consistently stored in a new, uncontaminated environment.

Chinese

Chinese España

España Italia

Italia Le français

Le français