The contents of the airless bottle can be completely isolated from the air to prevent the product from being oxidized and deteriorated due to contact with the air, and the breeding of bacteria, and its high-tech concept enhances the product level. The airless bottle in the market is composed of a cylinder into an ellipsoid container and a piston placed at the bottom. Its design principle is to use the contraction force of the spring to prevent air from entering the bottle, resulting in a vacuum state, and to use atmospheric pressure to push the piston at the bottom of the bottle forward. However, because the spring force and atmospheric pressure cannot give enough force, the piston cannot fit too tightly with the bottle wall, otherwise the piston will not be able to move forward due to excessive resistance; on the contrary, if the piston is to move forward easily and easily leak material Therefore, airless bottles have very high requirements for the professionalism of manufacturers.

Vacuum packaging technology

Vacuum packaging technology is a new concept with absolute advantages. This packaging technology has helped many new brands and new formulas go on the market smoothly. Once the vacuum packaging is assembled, from filling the packaging to the consumer's use process, almost minimal air can enter the container, contaminate or decompose the contents. This is the advantage of vacuum packaging-it provides a safe packaging empty for the product, avoids contact with air, reduces the most likely change and oxidation, especially the delicate natural ingredients that need to be protected, when avoiding the addition of preservatives Among the calls, vacuum packaging is more important to extend the shelf life of products.

Vacuum-packed products are different from standard pumps or spray pumps with common straws. Vacuum packaging uses the principle of separating the inner cavity to squeeze out the contents. When the inner diaphragm moves up to the inside of the bottle, a pressure is formed, and the contents are present in a vacuum state close to 100% at this time. Another vacuum method is to use a vacuum soft bag, placed inside a rigid container, the concept of use of the two is almost the same. The former is widely used and is a very important selling point for brands, because it consumes less resources and can also be regarded as "green".

Vacuum packaging also provides precise dosage control. When the discharge hole and the specific vacuum pressure are set, regardless of the matching head shape, each dosage is accurate and quantitative. Therefore, the dosage can be adjusted by changing a certain part, from a few microliters or a few milliliters, all according to the needs of the product.

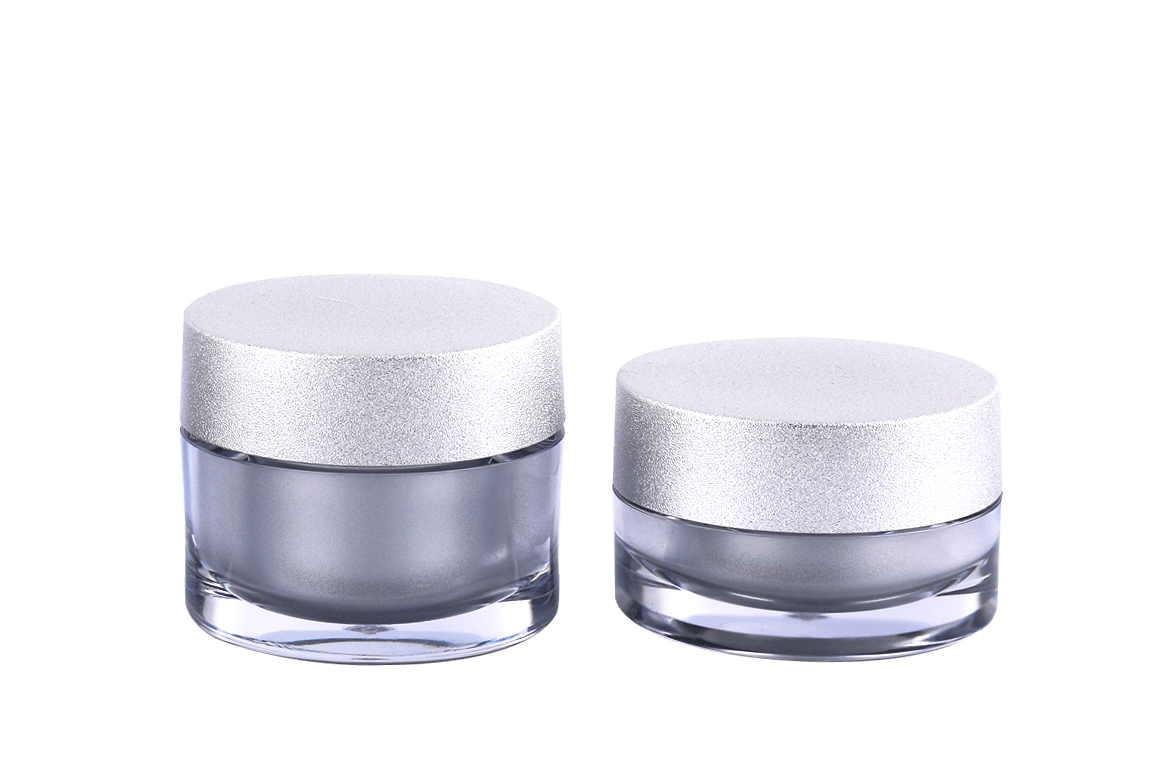

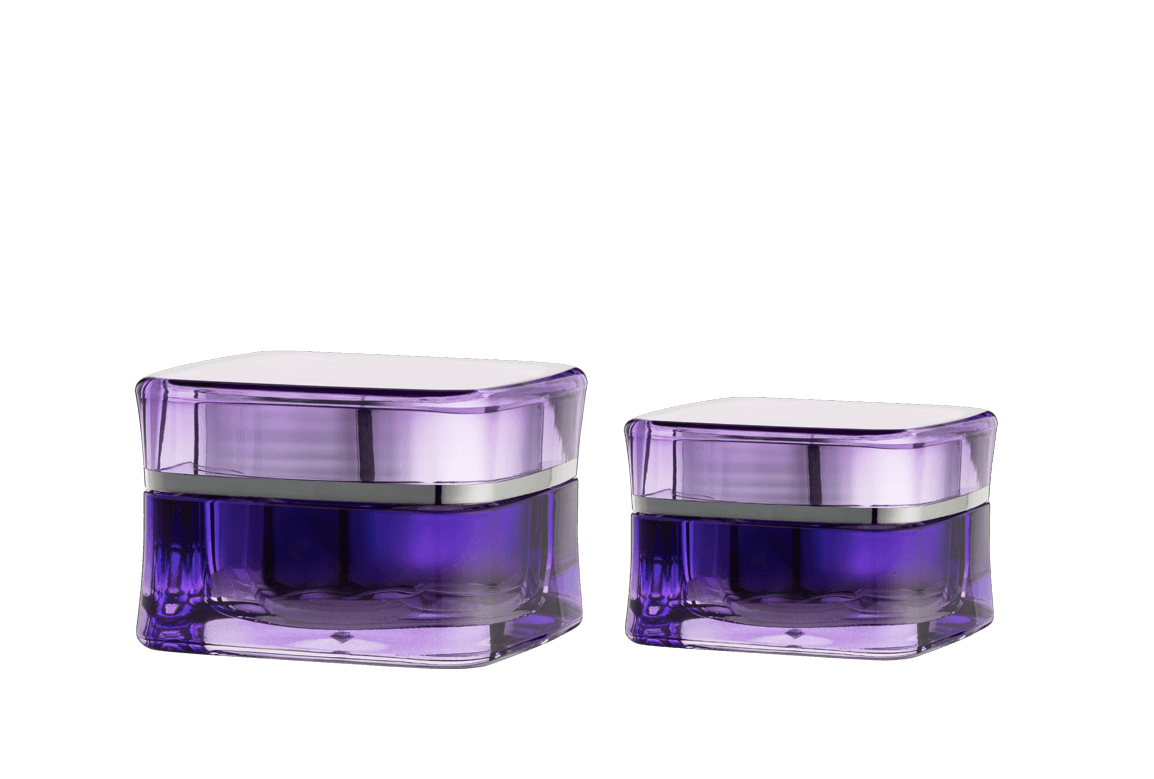

Product preservation and hygiene are the key values of airless bottle packaging. Once the contents are taken out, there is no way to put them back into the original vacuum packaging. Because the design principle is to ensure that every use is fresh, safe, and worry-free, the internal mechanism of our products, there is no doubt that the spring is rusted, and the contents will not be contaminated.

Consumers’ cognition also affirms the value of vacuum products invisibly. Compared with general standard pumps, sprays, straws, and other packaging components, vacuum packaging is smoothly used, with a fixed dosage and high-end appearance, making it occupy a huge market for luxury products.

Chinese

Chinese España

España Italia

Italia Le français

Le français