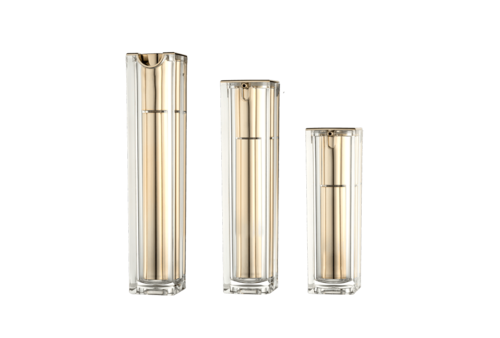

The airless bottle pressure pump has no suction tube, so that the inner material can be completely isolated from the air, avoiding the oxidation and deterioration of the product due to contact with the air, and the breeding of bacteria, and its high-tech concept enhances the product level. The airless bottle in the market is composed of a cylinder into an ellipsoid container and a piston placed at the bottom.

Its design principle is to use the contraction force of the spring to prevent air from entering the bottle, resulting in a airless state, and to use atmospheric pressure to push the piston at the bottom of the bottle forward.

The airless bottle is filled by a airless filling machine.

The airless filling machine is a machine that fills the bottle under the pressure lower than the atmospheric pressure. It uses continuous airless suction to draw the product into the container. The continuous suction is a airless pump connected to a airless chamber and a special filling valve. produce.

The process of filling cosmetics is not in a airless environment. After the finished cosmetics are filled into the container, the gas will be pumped away through the machine, making the bacteria lose the breeding ground for production. However, whether there are bacteria entering depends on the production process of the cosmetics and the preservation conditions during use.

The airless filling machine is a machine that fills the bottle when the pressure in the bottle is lower than the atmospheric pressure. It uses continuous airless suction to pump the product into the container. Its continuous suction is composed of a airless chamber and a special filling valve. The connected airless pump produces. The general process is: boxes with empty bottles are stacked on pallets, sent to the pallet unloading machine by the conveyor belt, the pallets are unloaded one by one, and the boxes are sent to the unloading machine with the conveyor belt, and the empty bottles are taken out from the box. The empty boxes are sent to the box washing machine through the conveyor belt, cleaned, and then transported to the boxing machine to load the bottles with beverages into them.

The empty bottles taken out from the unloading machine are sent to the bottle washing machine for disinfection and cleaning by another conveyor belt. After being inspected by the bottle inspection machine, they enter the filling machine and capping machine after meeting the cleaning standards. The beverage is filled into the bottle by the filling machine. The beverage bottles are capped and sealed by the capping machine and transported to the labeling machine for labeling. After labeling, they are sent to the cartoning machine to be put into the box and then sent to the stacker and pallet machine to be stacked on the pallet and sent to the warehouse.

Chinese

Chinese España

España Italia

Italia Le français

Le français