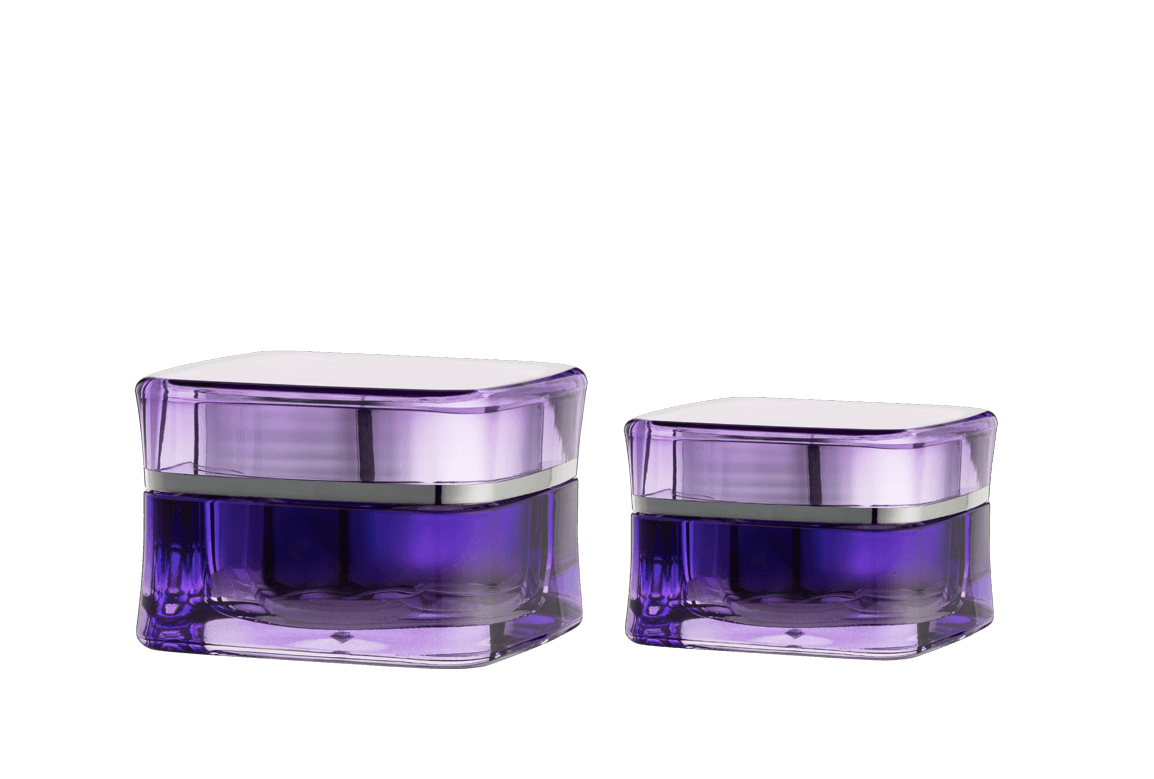

Acrylic cream jars are widely used in high-end cosmetic packaging due to their crystal-clear appearance and glass-like texture. However, the acrylic injection molding process is complex and demands extremely high standards for quality control. Any minor deviation in the process can lead to product defects, directly compromising the packaging's visual appeal and functionality. Professional manufacturers must strictly adhere to the following eight critical control points to ensure acrylic cream jars meet premium quality standards.

1. Raw Material Pre-treatment and Drying Control

Acrylic is a hygroscopic material. If PMMA pellets are not sufficiently dried before injection molding, residual moisture will vaporize at high temperatures, causing severe defects such as splay marks, bubbles, and surface hazing in the final product.

Key Control Points:

-

Dew Point Monitoring: Ensure the dew point temperature of the hot air dryer remains below -30 degree to guarantee drying efficiency.

-

Closed Conveying: Immediately convey the dried material to the hopper via a closed system to prevent reabsorption of ambient moisture.

2. Injection Temperature and Plasticization Uniformity

Acrylic requires precise temperature control during the molding process. Temperatures that are too low lead to excessively high melt viscosity, difficult filling, and the formation of stress and flow marks. Excessively high temperatures can cause material decomposition, resulting in discoloration or black specks (charring).

Key Control Points:

-

Multi-Zone Temperature Control: The injection machine barrel must be divided into multiple temperature zones, gradually increasing from the feed throat to the nozzle, ensuring smooth melt plasticization.

-

Screw Speed and Back Pressure: Employ low screw speeds and appropriate back pressure to ensure uniform material plasticization and to expel air from the melt.

3. Mold Temperature and Cooling Management

Mold temperature is crucial for the surface finish, internal stress distribution, and dimensional stability of acrylic products.

Key Control Points:

-

Precise Temperature Maintenance: Acrylic mold temperatures are typically maintained at a relatively high level, ranging from 60 degree to 85 degree.

-

Temperature Differential Control: Ensure the temperature difference between the mold cavity and core is minimized to prevent uneven cooling, which leads to warpage or inconsistent shrinkage.

-

Cooling Rate: Utilize a slower and uniform cooling rate, allowing time for PMMA molecular chains to relax. This significantly reduces the product's internal stress, which is key to preventing cracking during subsequent use.

4. Injection Pressure and Velocity Profile

Injection pressure and velocity are direct factors controlling the product's aesthetic defects and dimensional accuracy.

Key Control Points:

-

Multi-Stage Injection: Adopt a segmented injection speed profile, typically a "slow-fast-slow" pattern. The initial slow speed prevents jetting, the intermediate fast speed ensures full mold filling, and the final slow speed prevents overfilling or flashing.

-

Holding Pressure and Time: Holding Pressure is vital for compensating for material shrinkage and ensuring product density. The pressure must be sufficiently high but not excessive, and the time precisely controlled to guarantee the dimensional accuracy of the jar's threads and base.

-

Switchover Point: The transition point from the injection phase to the holding phase (V/P Switchover) must be accurately set, typically based on screw position, to avoid underfilling or overpacking.

5. Precision Control of Threads and Sealing Areas

The jar's threads and opening are the core functional areas that determine its sealing performance and the customer's user experience.

Key Control Points:

-

Thread Tolerance: Dimensional tolerances for the threaded section must be tightly controlled, ensuring a snug fit and smooth engagement with the cap, avoiding issues like overtightening or slipping.

-

Sealing Flatness: The flatness and perpendicularity of the jar mouth's sealing edge are critical for preventing cream leakage. High-precision inspection using a Coordinate Measuring Machine (CMM) or vision measuring system is regularly required.

-

Smooth Ejection: Special attention must be paid to the mold design and force applied for the ejection of the threaded section, preventing thread deformation or flashing due to demolding damage.

6. Aesthetic Defect and Surface Finish Inspection

The clear, flawless appearance of an acrylic jar represents its premium value; any visual defect is unacceptable.

Key Control Points:

-

Flow Marks and Weld Lines: Inspect the jar's surface under high-magnification light to ensure the absence of visible flow lines, weld lines, or splay marks.

-

Clarity: Verify that the product does not exhibit hazing or yellowing, which typically results from improper raw material or temperature control.

-

Foreign Matter and Black Specks: Strictly control the cleanliness of the production environment, preventing the mixing of dust, scorched material, or impurities. The finished product must be free of any black specks or foreign contaminants, both internally and externally.

7. Internal Stress Testing

Internal stress is the greatest hidden hazard in acrylic products. It may not be immediately visible, but it can lead to stress cracking during subsequent electroplating, spraying, or filling processes.

Key Control Points:

-

Polariscope Inspection: Use a Polariscope during batch production to regularly inspect stress concentration areas on transparent parts, such as gates, corners, and threads, quantifying the stress level.

-

Chemical Solvent Immersion Test: Regularly conduct a Solvent Stress Test, for example, by immersing the product in an acetic acid solution, to accelerate stress release and verify that the product does not crack within a predetermined time frame.

8. Cycle Stability and Post-Processing Compatibility

The stability of the molding cycle and subsequent post-processing directly affects the consistency of batch products.

Key Control Points:

-

Cycle Consistency: Closely monitor the injection cycle time, ensuring that every shot maintains identical times for plasticization, injection, holding, and cooling.

-

Post-Processing Compatibility: For acrylic jars destined for electroplating or spraying, the molded parts must meet specific requirements for surface cleanliness and the absence of mold release agent residue before secondary processing to ensure the adhesion of the plating or coating.

Chinese

Chinese España

España Italia

Italia Le français

Le français