Thermal Properties: The Basic Performance Limitations of Acrylic (PMMA)

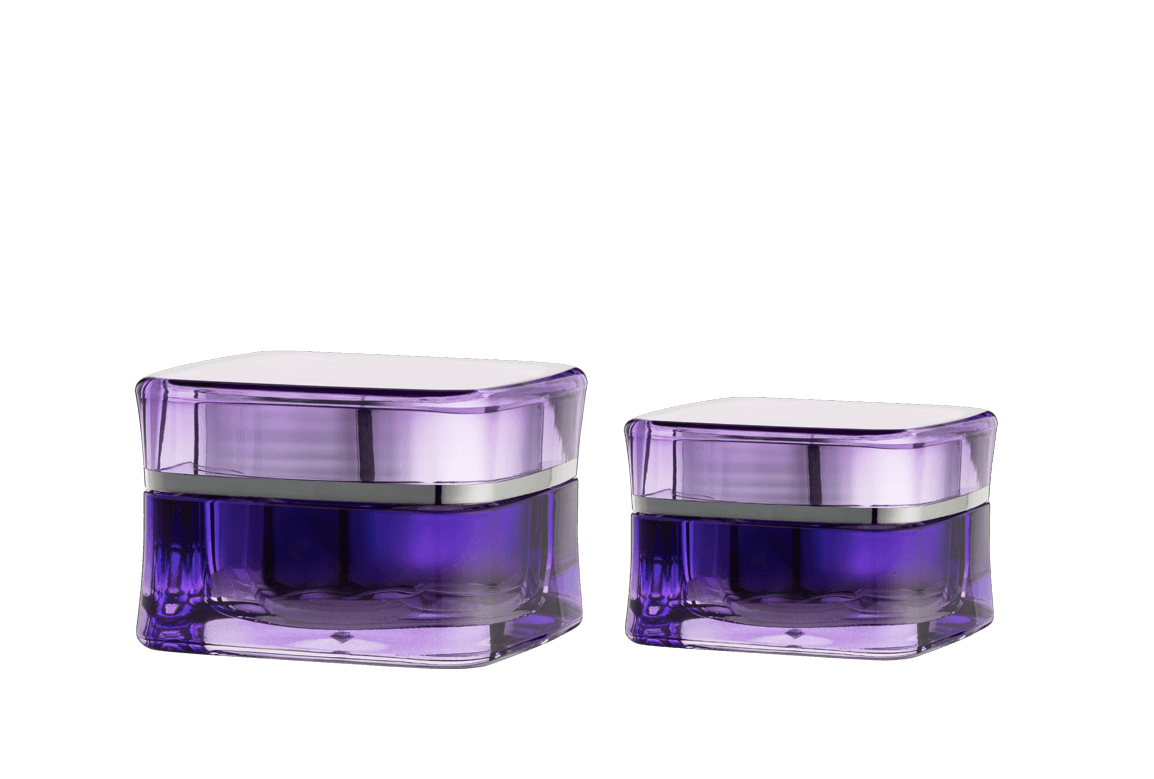

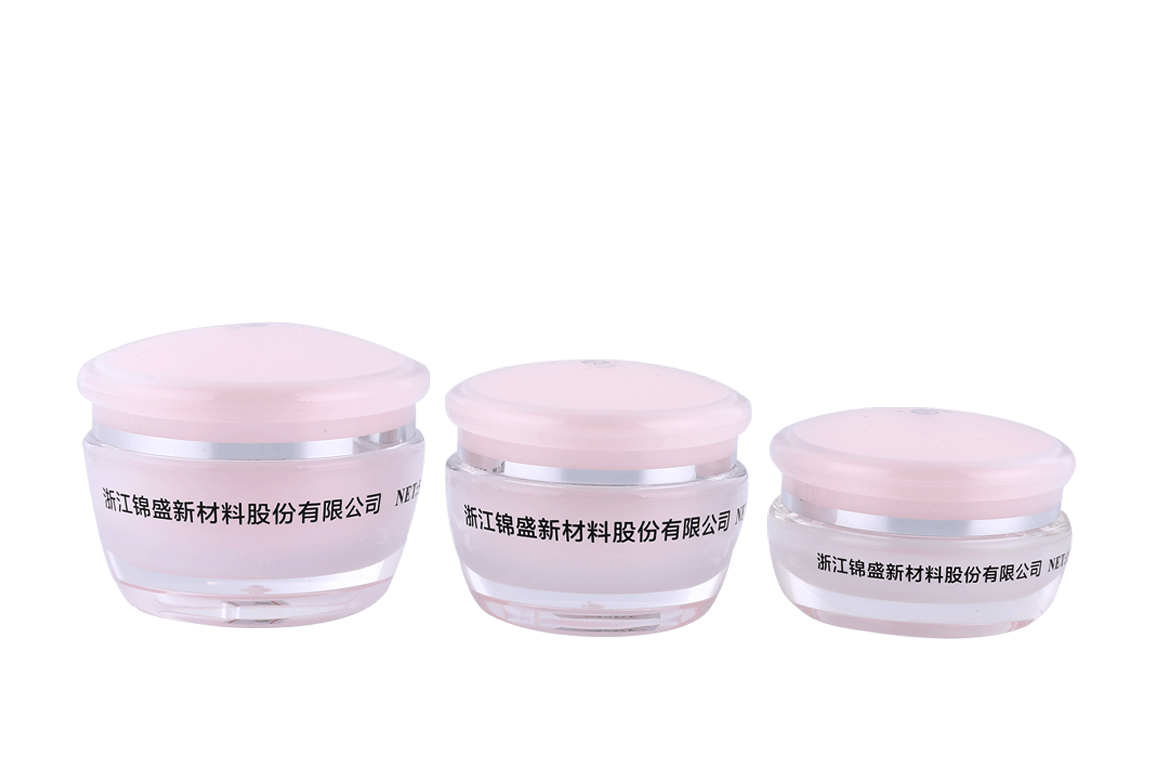

Acrylic (chemically known as polymethyl methacrylate, PMMA) is the material of choice for high-end cosmetic packaging, such as cream jars. However, its performance in extreme temperature environments, particularly dimensional stability and appearance integrity, is a key technical consideration that professional packaging suppliers and brand owners must thoroughly examine.

1. Glass Transition Temperature (Tg) and Thermal Deformation

As an amorphous polymer, PMMA's dimensional stability is determined by its glass transition temperature (Tg).

Tg Value: The Tg of standard PMMA is approximately 105°C. Below Tg, the material is in a glassy state, exhibiting high hardness and rigidity, and relatively stable dimensions.

High-temperature transportation risks: During high-temperature transportation (e.g., container temperatures can reach 60°C or even higher), even though the temperature may not reach Tg, prolonged exposure to temperatures close to the heat deflection temperature (HDT) can gradually release stress within the PMMA. This can cause slight deformation or warping of the bottle, impacting thread accuracy.

2. Impact of the Coefficient of Linear Thermal Expansion (CLTE)

Another key indicator of dimensional stability is the coefficient of linear thermal expansion (CLTE).

CLTE Characteristics: PMMA has a significantly higher CLTE than glass or metal. This means that the PMMA bottle expands more when the temperature rises.

Multi-layer structure challenges: Acrylic cream bottles often have a two-layer structure, with a PMMA outer layer and an inner liner typically made of PP (polypropylene) or PET (polyethylene terephthalate). Due to the different CLTE values of these two materials, when experiencing extreme temperature fluctuations (for example, temperatures dropping from 40°C to -20°C), the outer bottle and inner liner shrink/expand at different rates and magnitudes, easily generating stress between them. This stress can cause separation, gaps, and even compromise the seal.

Appearance Integrity: Visual Defects Under Severe Temperatures

The greatest advantage of acrylic bottles lies in their high transparency and crystal-clear appearance. However, high and low temperatures are the two main factors that cause appearance defects.

1. Coating and Printing Issues Under High Temperatures

Surface treatment is crucial to the aesthetics of acrylic bottles, but it is also their primary weakness under high temperatures.

Coating Blistering and Delamination: If the bottle is sprayed (color coating) or electroplated (metallization), high temperatures can accelerate thermal stress between the coating and the PMMA substrate. Poor-quality UV coatings or improper curing processes can cause bubbling, cracking, or decreased adhesion in the coating, leading to large-scale delamination.

Silkscreen/Hot Stamping Discoloration: The heat resistance of silkscreen inks and hot stamping materials used for logos and text is a key design consideration. Some organic pigments may degrade under high temperatures, resulting in color shift or fading.

2. Risk of Brittleness and Cracking at Low Temperatures

Extremely low temperatures, especially during transportation or storage in cold climates, can significantly affect the toughness of PMMA.

Decrease in Impact Strength: As the temperature decreases, the impact strength of acrylic material decreases significantly, making the material more brittle.

Cold Cracking: If internal stresses are present in the bottle during the injection molding process, these stresses may exceed the material's tensile strength at low temperatures when exposed to sub-zero temperatures. Slight mechanical shock (such as a drop during loading and unloading) or the spontaneous release of internal stresses can cause microcracks or even catastrophic failure, compromising the integrity of the packaging.

Professional Solutions: Thermal Cycling Testing and Quality Control

To ensure acrylic cream jars are safe for use in extreme global climates, professional packaging manufacturers must incorporate rigorous thermal cycling testing and environmental simulations.

1. Thermal Cycling

This test simulates the real-world environmental changes experienced when transporting products from hot to cold regions.

Testing Process: Finished bottles are placed in a high- and low-temperature cycler, typically undergoing rapid or gradual temperature changes between -20°C and +50°C for a specified holding time.

Evaluation Metrics: Observe the bottle's appearance (for cracks or coating peeling), dimensions (using calipers or a coordinate measuring machine to assess diameter and height variations), and, most critically, sealability (vacuum leak testing). Only products that maintain dimensional stability and cosmetic integrity through multiple cycles of thermal cycling are considered to meet high standards.

2. Material Modification and Optimization

Some high-end acrylic packaging materials utilize blending or copolymerization of PMMA with other polymers. This process, at the expense of some transparency, improves the high-density thermal conductivity (HDT) and low-temperature toughness, thereby enhancing its resistance to extreme temperatures.

Chinese

Chinese España

España Italia

Italia Le français

Le français